What is Floor Testing?

The Floor Slip Resistance Test

This is the use of specialist Floor Testing equipment to determine how 'slippery' a floor is. The Floor Pendulum Test is the primary equipment used in the UK for Floor Slip Testing for businesses as well as to provide robust test evidence in UK Courts of Law in respect to Floor Slip Injury Claims; find out more about Why Floors are Tested. The same floor testing equipment and methodology is used in many countries.

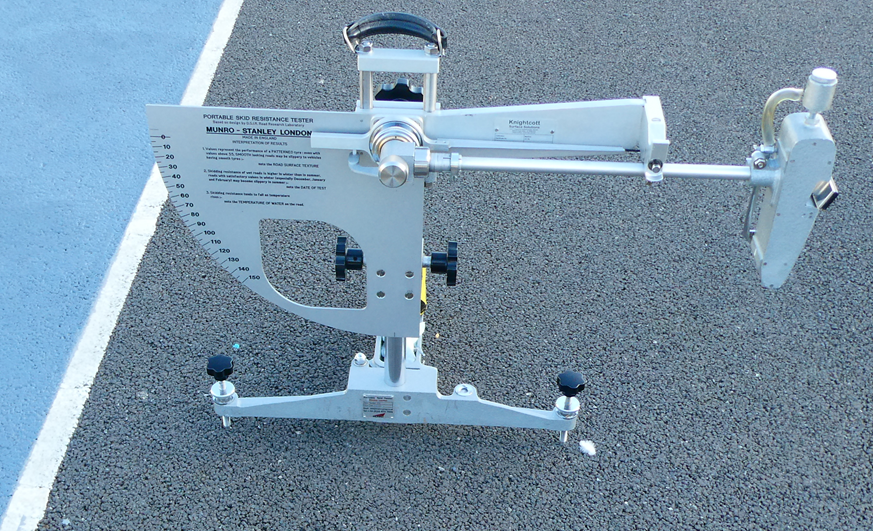

Floor Pendulum Test Equipment

Floor Pendulum Test Equipment

How does the Floor Pendulum Test Work?

Mounted on the foot of the pendulum arm is a Rubber Slider . The arm of the Pendulum is swung across the floor surface and the rubber slider, which is sping loaded, makes contact with the floor, the spring allowing the arm to go through its full arc. How far the pendulum arm travels determines the friction resistance, the further the swing goes, the more slippery the floor is especially when a floor is wet.

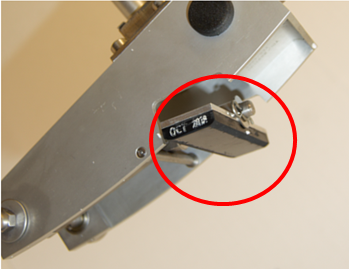

The rubber slider is of specific hardness. In the UK, a '96' slider is used to represent Shod Feet and a (softer rubber) '55' or '57' Slider used to represent bare feet or profiled surfaces. Values 55, 57, and 96 determined by SHORE hardness test (BS ISO 48:2010).

Rubber Sliders

Rubber Sliders

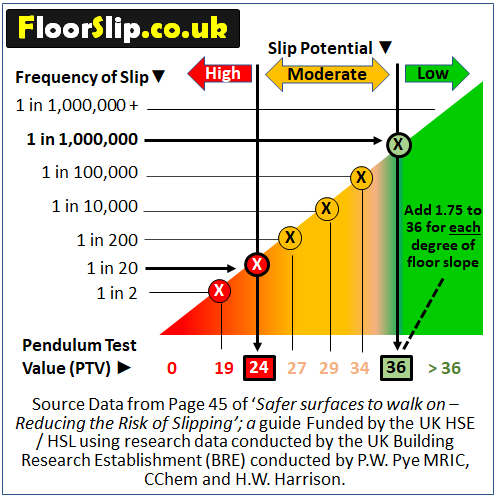

What Pendulum Test Value (PTV) Results are Required?

The UK HSE have determined a WET TESTED FLOOR Pendulum Test Value (or 'PTV') of 36 PTV should give a LOW Potential of Slip on a horizontal slope (Adjusted UPWARDS by 1.75 PTV for every 1 degree of Floor Slope). Anything less than 36 PTV 'might' be acceptable provided ALARP has been met; but in all cases, any environment likely to get wet on a regular basis should have a minimum 36 PTV. Also, note well that floors wear so aim higher than the minimum of 36 PTV.

Floor Surface Roughness Testing

...Is also carried out on floors to compliment the Pendulum Floor Testing (but not to replace it). The floor testing equipment drags a needle across the floor to determine the 'microroughness' to arrive at 'Rz' value measured in micrometres (tiny values!). The theory is that the rougher the floor surface, the less likely that a slip on a floor will occur. However, when seen under a microscope, surface profiles vary and some will grip better than others even if the Floor Surface Roughness Tests arrived at the same values. It is however a great tool for monitoring floor surface changes over time. It can also be used on surfaces like metal, where a desired surface roughness level is required prior to plating or painting etc.

Floor Surface Roughness Test Equipment

Floor Surface Roughness Test Equipment

(Second Variety)

(Second Variety)

Ramp Testing - R Ratings and ABC Ratings

Always Pendulum Test a Floor Sample of an R-Rated floor before fitting or at first fit, note that the Prices of Floor Sample Tests are very affordable through FloorSlip

Ramp Testing is the action of a person slowly stepping forwards and backwards on a floor surface which is raised until the person slips and a slope value is recorded which is given a rating. 'R-Ratings' are given where cleated workboots are worn and oil is sprayed onto a specific floor surface that a manufaturer may want testing (see the image below of ramp testing). R Ratings start at R9 (shallow angle) and go up to R13 (steep angle). Consider this, do you think most of your customers and staff will be wearing workboots and walking on oil? Highly Unlikely! Hence why the Ramp Test does not supersede the Pendulum Floor Test, the Pendulum Test gives truer, more accurate and repeatable determination of slip potential.

'ABC Ratings' are for the bare foot environment using water instead of oil. ABC Ratings start at A -Rating (shallow angle slope) to C-Rating (steepest angle slope)

The Shod Floor Ramp Test

The Shod Floor Ramp Test

The operator is walking on an inclined floor covered in oil whilst wearing work boots. This test determines the R Ratings

The Bare Foot Floor Ramp Test

The Bare Foot Floor Ramp Test

The operator is walking on an inclined floor covered in water whilst bare foot. This test determines the ABC Ratings (For Swimming Pools, Jacuzzis, Shower Rooms, Changing Rooms etc.)