Road and Airfield Surfaces Skid Test Standards

The slip / skid resistance of Road and airfield surfaces are tested under BS-EN-13036-4:2011, the Pendulum Tests, as issued by the British Standards Institute

(ISBN 978 0 580 76160 7 Refers)

IMPORTANT NOTE – BSI states that BS-EN-13036-4-2011 supersedes BS-7976 (Parts 1,2,3). THIS IS INCORRECT BUT THE STATEMENT HAS STILL NOT BEEN REMOVED BY THE BSI.

BS-EN-13036-4 was released in 2011 exclusively for roads and airfields, whereas, BS-7976-2 is mainly used for pedestrian surfaces (and occasionally roads); BS-7976-2 is being superseded by EN-16165:2022 (See Floor Test Standards). Note that BS-EN-13036-4, BS-7976-2 and EN-16165 all use EXACTLY the same Floor Pendulum Test Equipment in virtually the same manner with minor exceptions, which are discussed further below...

BS-EN-13036-4 (i.e., Part 4) is just one standard in a series of standards, including:

- EN 13036-1, Road and airfield surface characteristics. Part 1. Test methods. Measurement of pavement surface macrotexture depth using a volumetric patch technique

- CEN/TS 13036-2, Road and airfield surface characteristics. Part 2. Test methods. Assessment of the skid resistance of a road pavement surface by the use of dynamic measuring systems

- EN 13036-3, Road and airfield surface characteristics. Part 3. Test methods. Measurement of pavement surface horizontal drainability.

- EN 13036-4, Road and airfield surface characteristics. Part 4. Test methods. Method for measurement of slip/skid resistance of a surface — The pendulum test

- PrEN 13036-5, Road longitudinal evenness; Part 5. Definition & calculation methods of the longitudinal evenness indices

- EN 13036-6, Road and airfield surface characteristics Part 6. Test methods. Measurement of transverse and longitudinal profiles in the evenness and megatexture wavelength ranges

- EN 13036-7, Road and airfield surface characteristics. Part 7. Test methods. Irregularity measurement of pavement courses: the straightedge test EN 13036-8, Road and airfield

Method of use of BS-EN-13036-4

To reiterate, BS-EN-13036-4, BS-7976-2 and EN-16165 all use EXACTLY the same Floor Pendulum Test Equipment in virtually the same manner.

The exceptions are subtle changes as described here:

1. The Pendulum Verification Values– use the link to find out more

2. Wet Testing the Road Surface Under BS=EN-13036-4. Wet floors, roads or airfield surfaces are far less able to resist slips than Dry surfaces. For floors and pedestrian surface testing (BS-7976-2 and EN-16165) a small spray of water is applied during test. But on road / airfield surfaces, copious amounts of water are applied when wet testing under BS-EN-13036-4 as it is likely that the external road surface tested will be more porous than, for example a floor surface in a shopping centre; or will drain rapidly due to slope. At least 100 ml of water may be required to be applied to the surface and the slider at each pendulum test swing; applying too little water may give erroneous results.

3. Test Criteria. A minimum of three test positions shall be selected but no more than 400 mm apart to then obtain a mean (average) value for a location from the 3 readings (this differs from BS-7976-2 and EN-16165). If the first five swings differ by more than three (PTV) units, then the test must be repeated until three successive readings are constant.

4. Tolerances in Testing – In section 13 of BS-EN-13036-4 the subject of deviation across tests is discussed where eleven different European laboratories participated in testing of twelve different material surfaces when WET using slider #96 and #57 (or #55? – See Note 2 at the bottom of the page). They concluded that standard deviation occurred as follows: -

- Slider 96: From 1.5 to 4.5 PTV. Average standard deviation of 2.4 PTV units.

- Slider 57: From 1.4 to 3.9 PTV Average standard deviation of 2.6 PTV units.

NOTE CAREFULLY - It has been fedback from the UKSRG that the the ‘Average Standard Deviation’ should NOT be applied in real world testing and this deviation data is NOT included or applicable in BS-7976-2 (2002/2013) or EN-16165(2022).

5. Slider Length Measurement - The British Standard reports that the sliding length measurement at the ground shall be at 126 ± 1 mm for the wide slider (same as from BS-7976-2 and EN-16165) and 76 ± 1 mm for the narrow slider. WE THINK THE NARROW VALUE IS INCORRECT IN BS-13036-4 as the slider dimension in the ‘direction of swing’ of 25.4mm does not change and therefore the sliding length measurement at the ground should remain at 126 ± 1 mm. (Refer to Note 1 at the bottom of the page for Dimensions).

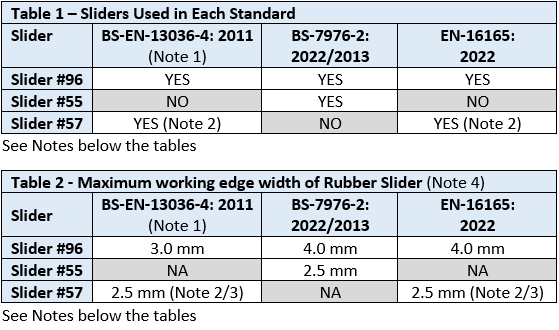

6. The Rubber Sliders. In Pendulum Testing, Rubber Sliders are used to represent a shod foot or a bare foot, the slider passes along and in contact with the floor surface on a Pendulum Arm; the further the travel along the floor, the less able the floor is to resist slips. The same sliders are used for road surface testing. The sliders across the industry come in three hardnesses known as the IRHD or 'International Rubber Hardness Degree'. The values include #55 (Softest), #57 to #96 (Hardest). The following tables give the comparisons of rubber sliders, which must be read in conjunction with the notes below the table.

Table 1 and 2. Rubber Sliders used in Pendulum Tests

NOTES – In respect to the text and tables above

- Note 1 - Has a choice of 2 slider widths in #96 and #57 (But also see Note 2)

- WIDE SLIDER (Standard) Slider 76.2mm wide x 6.35 mm thick x 25.4mm in the direction of swing

- NARROW SLIDER 31.75mm wide x 6.35 mm thick x 25.4mm in the direction of swing. (PTV results must be multiplied by 1.1 when using a ‘Narrow Slider’ to obtain an estimated true PTV within 10 %).

- Note 2 - Slider #57 has never been available to purchase since the release of BS-EN-13036-4 in 2011 and this is still the case in 2023, so Slider #55 is used instead. This means in effect, the use of BS-EN-13036-4 or BS-7976-2 or EN-16165 is virtually identical.

- Note 3 – Slider #55 and Slider #57 are both limited to 2.5mm maximum working edge

- Note 4 – All sliders have a minimum working edge of 1.0mm