On Site Floor Testing

On-Site Floor Pendulum Testing is assessing the ability of a floor to resist slips and to meet the UK Legal Requirements for Safe Floors.

How is the floor tested?

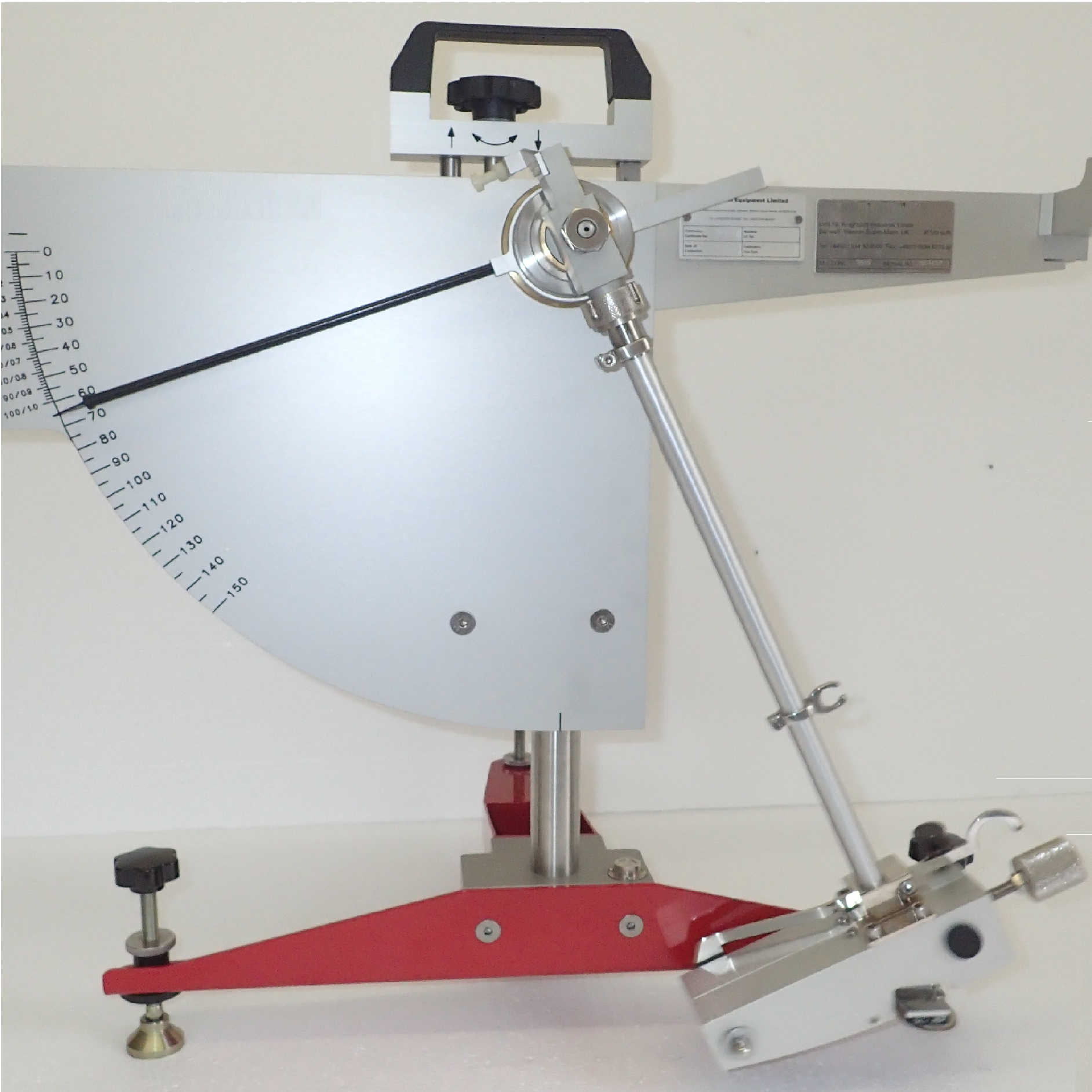

By use of Floor Pendulum Testing Equipment. The equipment is setup on the floor and a Pendulum Arm is released. Attached to the foot of the pendulum arm is a spring loaded ‘Rubber Slider’ of hardness value ‘55’, '57', or ‘96’ (EN-16165). The slider will slow down when it makes contact with the floor, the quicker it slows, the better the slip resistance and the safer the floor. Tests are conducted in Dry, Wet & Contaminated conditions. The floor always passes the test when the floor is DRY so only the WET / CONTAMINATED values should really be considered.

What Test Results am I looking for?

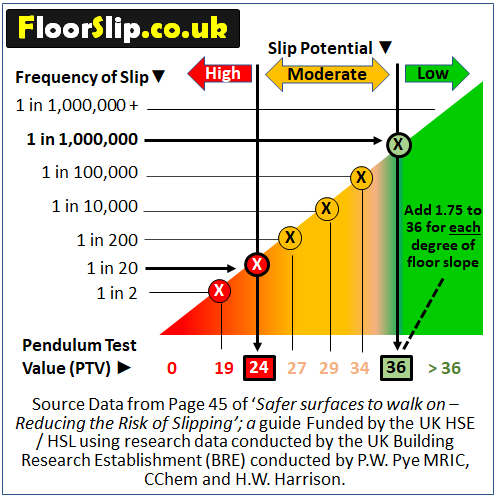

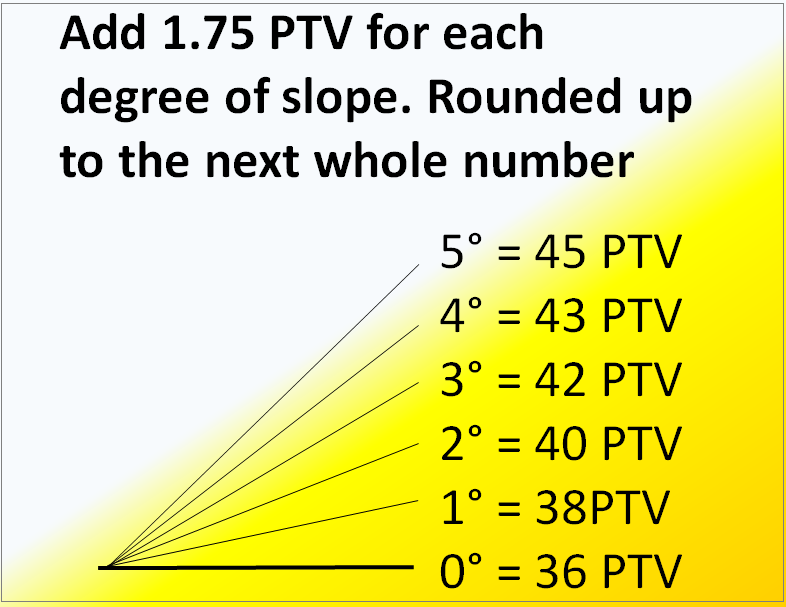

The UK HSE state a ‘Safe Floor’ should ideally have a ‘Low Potential of Slip’ proven by getting a Pendulum Test Value of 36PTV on a horizontal surface (0 degrees of floor slope*) when the floor is WET / CONTAMINATED. This should reduce the ‘Frequency of Slip’ to as low as 1 in 1 million.

The image below shows the ‘Potential of Slip’ and ‘Frequency of Slip' (Probability) for various PTV.

*NOTE - Adjust 36 PTV upwards by 1.75 PTV for every one degree of floor slope.

When should floors be tested for slip resistance?

It is suggested: -

- Annually as part of Risk Assessments

- Quarterly as part of Monitoring Floor Wear

- As a result of slip and fall which causes concern or results in a someone Making a Slip Injury Claim; we specialise in providing Expert Witness Reports in Slip Injury Claims

What if I have a floor test and cannot achieve 36 PTV?

There are a number of things that can be considered…

- Have a Non-Slip Floor Coating Applied

- Change the flooring to one with the required non-slip potential; see Buying New Floors

- Effectively demonstrate that the floor can be maintained in a dry and clean state for most of its usage and where the occasional floor contamination does occur, that fast and effective response to addressing the issue can be provided. This is known as (Floor Safety) ALARP.

How much does it cost to test floors on site?

See our Prices of Floor Testing

How Quickly can you Test my Floor on site?

We can respond within 24 hours, especially in the case of a making a slip injury claim

Where do you test?

We conduct on-site tests all across the UK (except Eire/ N. Ireland). The alternative is to send a Floor Sample for Testing where it is practical to do so as we can conduct sample testing for our clients worldwide.

What Standards do FloorSlip Test to?

We test to EN-16165 (Paralleling / Superseding BS-7976-2 in 2021/22) and in accordance with UKSRG Guidelines