UK Floor Surfaces Testing Standards

There are a multitude of Floor Surfaces Testing Standards but the MAIN 'Floor Test' standards issued for use in the UK and European arenas of Floor Slip Resistance Testing are as follows...

1. (Main #1) Floor Pendulum and Floor Ramp Floor Test – BS-EN-16165

Released in Dec 2021 with corrections for release in Feb 2022, European Standard EN-16165 (ISBN 978 0 539 21258 7) is the latest standard for testing of slip resistance of pedestrian surfaces covering four Methods of evaluation. It has been adopted for use in the UK and is available in English, French and German. EN-16165, issued completely replaced / superseded existing BS-7976-2:2002+A1:2013 (pendulum tests) withdrawn Feb 22 and DIN 51097 / 51130 (Ramp Tests) and a host of other standards.

BS-EN-16165 includes 4 annexes as follows: -

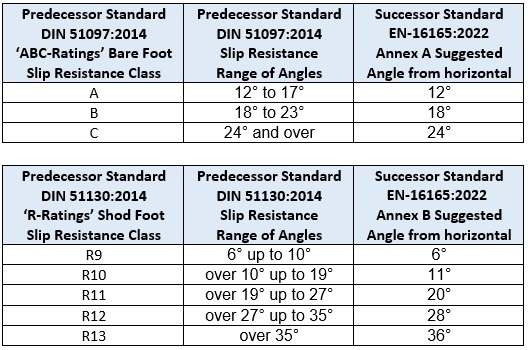

- BS-EN-16165 - ANNEX A - To supersede: DIN 51097 (2014) – Ramp Tests – Bare Feet

- BS-EN-16165 - ANNEX B - To supersede: DIN 51130 (2014) – Ramp Tests – Shod Feet

- BS-EN-16165 - ANNEX C - To supersede: BS-7976-2 (2002/2013) - Pendulum Tests

- BS-EN-16165 - ANNEX D - New: Tribometer Test used in Europe and USA but rarely in the UK

- BS-EN-16165 - DOES NOT COVER - Non-Pedestrian Surfaces (Roads / Airfields), which should be tested under BS-EN-13036-4

NOTE - The BS-EN-16165 test methods at Annex A, B, C and D cannot be compared with each other. Results can only be compared with results obtained within the same ANNEX.

2. (Main #2) UKSRG Guidelines on Pendulum Testing

The UKSRG (UK Slip Resistance Group) are a body of leading industry experts regularly issue comprehensive Guidelines on Pendulum Testing, wholly supporting and adding supporting data for superseded BS7976-2 and current BS-EN-16165 standards and should be used in conjunction with the Standards. The guidelines are recognised in UK courts in Slip Injury Claims and also used by authorities outside of the UK. UKSRG Guidlines Issue 5 align with BS-7976-2 and UKSRG Guidlines Issue 6 align with BS-EN-16165.

3. Pendulum Floor Test Standard – BS-7976-2: 2002+A1 2013

Superseded / Replaced by BS-EN-16165 in Feb 2022

British Standard BS-7962-2:2002 + A1:2013 has underpinned UK Floor Pendulum Testing for two decades until Feb 2022, when it was withdrawn. BS-7976 was split into 3 parts. Part 1: Specification; Part 2: Method of operation: Part 3: Method of calibration. BS-7976 has now been superseded by BS-EN-16165 (Feb 22). The differences between the BS-7976-2 and BS-EN-16165 in respect to the Pendulum Tests are marginal; the Pendulum Test Value (PTV) results expected are the same.

4a. Floor Ramp Testing (Shod Feet) DIN* 51130

(Hinted at as being Superseded / Replaced by BS-EN-16165)

*DIN stands for 'Deutsches Institut für Normung', meaning 'German institute for Standardisation'. DIN 51130 determines values termed ‘R-Ratings’ ranging from R9 to R13 achieved using the Ramp Test. The R-Ratings being indicative of the amount of expected slip that a floor surface might cause, the higher the value (R13 being highest) the better the floor slip resistance.

4b. Floor Ramp Testing (Bare Feet) DIN 51097

(Hinted at as being Superseded / Replaced by EN-16165)

DIN 51097 standard arrives at values termed ‘ABC-Ratings’ achieved using the Ramp Test. The ratings being indicative of the amount of expected slip that a floor surface might cause in wet environments such as showers, swimming pools or Jacuzzis, the higher the value (C being highest) the better the floor slip resistance.

Anomalies with EN-16165

Anomalies with EN-16165 Annex A / B - Ramp Tests

The forward of EN-16165 fails to state it supersedes DIN 51130 or 51097. The older DIN Standard Tests arrived at a angular value via a Ramp Test, which was translated to ABC Ratings or R-Ratings. The new standard EN-16165 at Annex A (Barefoot) and Annex B (Shod foot) also uses the Ramp Test, but the results do NOT translate to ABC Ratings or R-Ratings; the results instead in EN-16165 are given as a SINGULAR ANGULAR VALUE.

The BS-EN-16165 result gives no indication to determine the True Dynamic Measure of Slip, which can only be determined, post RAMP Test, in the 'Real World' by a Floor Sample Pendulum Test to Determine the Dynamic Coefficient or PTV. The PTV (Pendulum Test Value) is the value most recognised in Court or by the UK HSE.

The options available therefore are...

(1) Continue using DIN standard testing when DIN 51130 ABC Ratings or DIN 51097 R Ratings are required - followed up by Pendulum Testing

(2) Or, possibly use the single value obtained under BS-EN-16165 to read across to the DIN Standard R-Rating or ABC Rating - followed up by Pendulum Testing

Anomalies with BS-EN-16165 - Pendulum Testing (Annex C)

BS-EN-16165 Annex C was supposed to replace BS-7976 Pendulum Test Standard (all 3 parts) from Feb 2022 but did not fully do so due to the inability to purchase 'Slider 57' in the UK. Instead 'Slider 55' is used (as originally called up in BS-7976-2). The National Foreword of BS-EN-16165 states 'Slider 55 rubber has been in use in the UK for several decades, and the UK committee considers it to be the preferred alternative to slider 57 rubber, which is specified in EN 16165:2021. NOTE Slider 55 rubber as supplied is normally within the specification range of slider 57 rubber'

Read more detail about Rubber Sliders

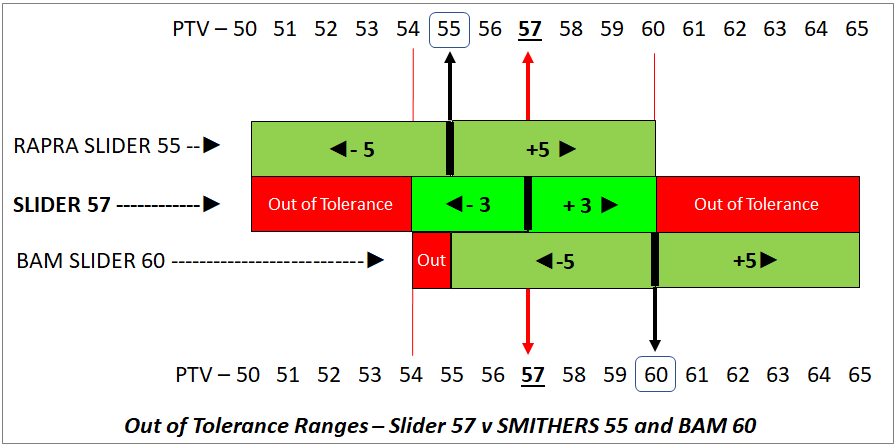

Main Problem - The last line of the extract states'...'Slider 55 rubber as supplied is normally within the specification range of slider 57 rubber'. There are 3 issues here: -

Issue 1. Under BS-7976-2, a rubber slider #55 is used and under BS-EN-16165, a rubber slider #57 is used but slider #57 is not yet available to purchase in the UK nor is it manufactured and may not be for some years (if at all).

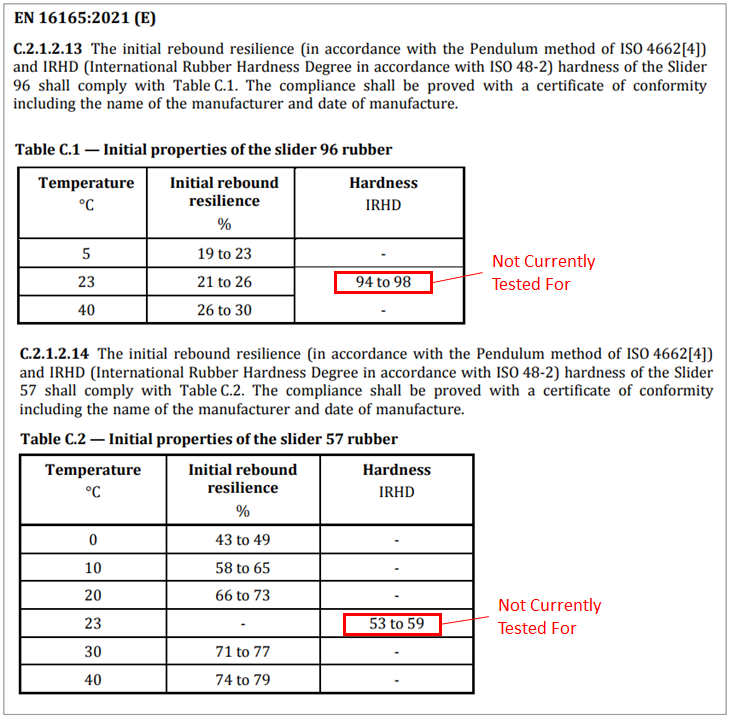

Issue 2. Where slider #55 is used as substitute for slider #57 in BS-EN-16165, it requires an alignment of manufacturers specifications. This cannot be achieved in some cases for just one criterion (hardness tests by manufacturers at 23 Deg C) and in some cases by a few criterion (See the 2 images below)

Issue 3. The slider #96 specification BS-EN-16165 expects hardness tests by the manufacturers at 23 Deg C; this is not currently done.

Background to the Problem - Slider #55 is manufactured by ‘Smithers MSE’ (UK) (Note 1) and is typically used in the UK only. ‘BAM’* (German) (Note 2) manufacture a slider #60, used by the Europeans. But neither Smithers nor BAM produce a slider #57. It is believed the #57 value was arrived at as a theoretical compromise between the #55 and #60 as an intent to provide a homologated common value across the UK and Europe and therefore suitable for use in BS-EN-16165. In conclusion, neither Smithers or BAM produce a Slider that fulfils the need of BS-EN-16165 but both Europe and the UK are expected to use BS-EN-16165.

* Note 1 - Smithers previously known as RAPRA (Rubber and Plastics Research Association).

* Note 2 - BAM (Bundesanstalt für Materialforschung und -prüfung) – i.e., German Institute for Materials Research and Testing.

IMAGE - 'Tolerance Ranges' for Slider #55, #57 and #60

IMAGE - Extracts of Table C1 and C2 from EN-16165 - Tables C1 and C2 of BS-EN-16165 expects a Hardness Test at 23 deg C; this is not currently conducted by the UK or European manufacturers so a 100% marry up between slider #55 and slider#57 is not possible at this time.

Suggested Interim Fix - Pendulum Floor Test Standards

NOTE - These are only suggestions; FloorSlip are not in position to act as an authority or reinforce these suggestions.

- Where slider #96 is used in conjunction with BS-EN-16165, state Slider #96 can not meet the full specification of BS-EN-16165 as the manufacturers do not product test at 23 deg C i.a.w. EN-16165 Table C1 (see image above).

- Where slider #55 is used in the place of slider #57 in conjunction with BS-EN-16165, then state that Slider #55 can not meet the full specification of EN-16165 as the manufacturers do not product test at 23 deg C i.a.w. EN-16165 Table C2.

- It is still unclear what can be claimed if slider #55 slider certification proves that the slider falls OUTSIDE THE RANGE shown in the 'Tolerance Ranges' (image above) as BS-7976-2, which would allow its use, has been withdrawn.

BS-EN-16165 - PRINCIPLE POINTS

Covered below are the principle points covered by Floor Testing Standard BS-EN-16165

BS-EN-16165 Ramp Tests - ANNEX A (Bare Foot) / ANNEX B (Shod Foot)

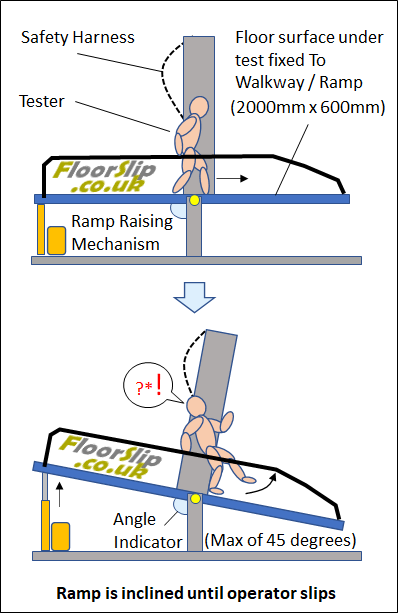

Overview - This topic is covered in more detail on the section on Ramp Testing. Briefly though, both the (predeccessor) DIN Standard 51097/51130 and the (successor) BS-EN-16165 Ramp Tests uses a floor surface than can be inclined from horizontal to which the floor to be tested is affixed to. An operator walks forwards in small steps either on bare feet or shod whilst a contaminant is sprayed onto the floor and the floor surface is incrementally raised in degrees of angle from horizontal until the operator slips. The angle is then measured and the results recorded thus:

- (Successor) BS-EN 16165 - Single Value of Angle that the operator slipped at.

- (Predecessor) DIN Standard 51097 - Angle equating to an A, B or C Rating

- (Predecessor) DIN Standard 51130 - Angle equating to an R Rating (R9 to R13)

IMAGE - EN-16165 Ramp Test Perfomed by Operator

Overview of Ramp Testing Procedure under BS-EN-16165

1. The test is only suitable for laboratory testing and not in-situ (floors on-site) testing

2. A rigid test platform 2000mm long x 600mm wide has a test piece (i.e., the flooring sample) affixed to the paltform (ramp floor) at a minimum size of 1000mm x 400mm

3. At least two ‘trained’ persons are required to conduct the test, individually, ‘walking the ramp’; training may include for example: gait, walking speed and skin condition (bare foot).

4. The testers are either bare foot (BS-EN-16165: Annex A). Or shod (BS-EN-16165: Annex B) with footwear of a specific rubber hardness of sole / heel and profile as the image below shows. The rubber will be Shore A hardness 73 ± 5 to EN ISO868. The profile is supplied from the German Supplier List (= Lieferantenliste) for testing-materials at Deutsche gesetzliche Unfallversicherung, Fachbereich Handel und Logistik,

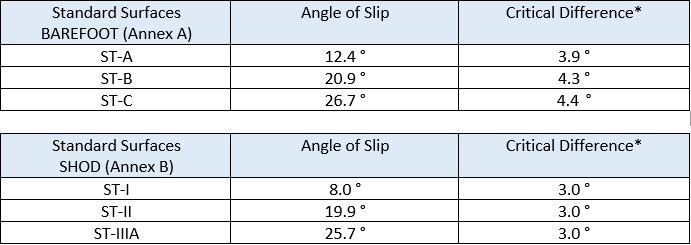

5. Three ‘Standard Surfaces’ (see table below) are used for the ‘training’ of the testers as well as verification and correction of test results.

6. The testers walk downslope only at 144 steps per minute in a half-gait.

7. The test surface is either (for the barefoot test) continuously coated with water containing a low foaming soapy solution and is at a temperature of 29°C ± 2°. Or (shod test) coated with 200ml of Motor Oil of grade SE 10W-30.

8. The tested surface should be tested in ‘at least’ 2 directions longitudinally (0°) and laterally (90°) to determine if there is directionality of slip. The direction of the lowest slip resistance (lowest ramp test angle) should be the determining result (In pendulum testing, 3 directions are tested including at 45°).

9. Each tester walks the ramp until a slip occurs and this is repeated until 2 slips at the same angle occur; this scenario is repeated 4 times by each tester. Only the average (mean) of last 3 sets of results from each tester are used in the next step, which is the verification.

10. The results from the tests are compared with the Standard Surfaces Table (see below) and if there is a ‘Critical Difference’ greater than that shown in the table, then the test is repeated with different test person ‘walking the ramp’.

11. Once all tests meet, or are inside the ‘Critical Difference’ value, then the test value recorded in the tests is the result used.

Notes – The Flooring Manufacturer’s instructions for cleaning of the floors under test may be useful and may form part of the test particularly as body fats (oil and sweats exuded) might affect the test results in the barefoot tests.

Tables of Standard Surfaces

*The Critical Differences are determined according to ISO 5725-2 or ISO 5725-5.

The Ramp 'Test Report' subsequently gives: -

- Standard and method Used in Test (i.e., BS-EN-16165 Annex A (Barefoot) or Annex B (Shod)

- Test organisation, name of person responsible for the test, date of test etc.

- Date of Calibration of Ramp

- Floor surface tested – company ident, finish, colour, dimensions etc.

- Ramp Test Value Angle Result to 0.1° – Rounded to the nearest 1 whole degree*

- Any additional comments

The test result gives a singular test value, which is meaningless when considering the ability of the floor to resist slips. Always specify a Floor Sample Pendulum Test is conducted as well when determination is required check a Floor is safe to meets UK HSE Expectations and Laws.

BS-EN-16165 ANNEX C – Pendulum Test (Pedestrians)

The main 'Differences' between the predecessor BS7976-2 and successor BS-EN-16165 are covered below this next section

Overview – BS-EN-16165 is for PEDESTRIAN SURFACES ONLY. Use BS-EN-13036-4:2011 for Road and Airfields traffic Pendulum testing, noting that BS-EN-13036-4:2011 also works with the SAME Pendulum Test Equipment used in BS-7976-2 and BS-EN-16165.

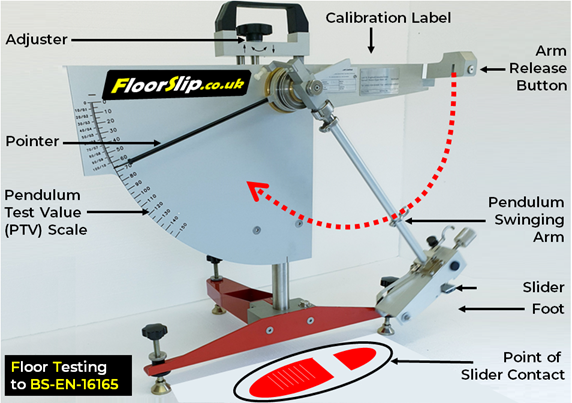

The Pendulum Floor Friction Slip Resistance Tester measures the dynamic Coefficient of Friction (CoF) of the floor surface when interacting between the sole / heel of a pedestrian and a Rubber Slider, which is part of the Pendulum Test Equipment. The test value arrived at is known as the Pendulum Test Value or ‘PTV’. Also see What is the Pendulum Floor Testing? And Why Floor Test?

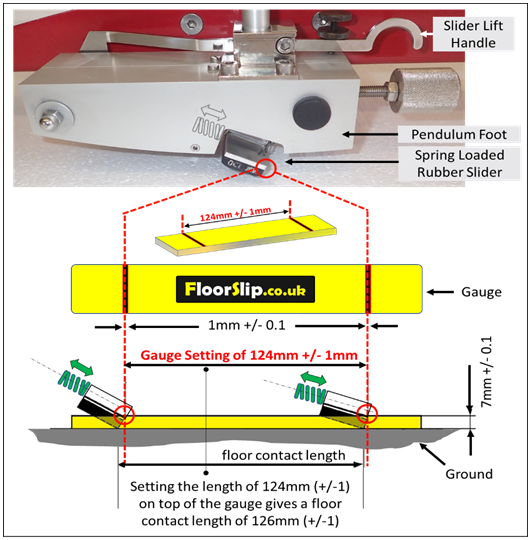

Image - The UK Manufactured Pendulum Floor Testing Equipment

The Floor Test works by the action of spring loaded Rubber Slider (Conditioned before use) mounted on the foot of the Pendulum Swinging Arm coming into contact with the floor surface and it is this slider that imitates either shod or barefoot conditions. The further the Pendulum arm swings after the rubber slider makes contact with the floor, then the worse the slip resistance; ideally a Pendulum Test Value of 36PTV at 0 degree slope when the floor is wet is required to ensure a suitable minimum probability of slip.

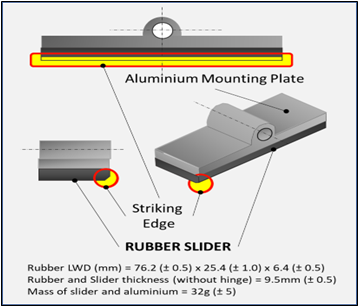

The rubber sliders specified in BS-EN-16165 are IRHD* of: -

- #96 Shod Feet

- #57* or #55 Bare Feet / Profiled Surfaces

(*Note that #57 is not manufactured nor available at the current time in the UK) see the earlier discussions on this page about this topic or refer to the page on Rubber Sliders

*IRHD = International Rubber Hardness Degree; the lower the number, the softer the rubber compound

Rubber Slider #96 (Historically known as ‘4S’ or Standard Shoe Sole Simulating) is used on the Floor Pendulum Test for pedestrian walkways and is used to replicate everyday use with shod feet

Rubber Slider #55/#57 is used on the Floor Pendulum Test for pedestrian walkways and is used to replicate bare feet in environments such as swimming pools and changing rooms; it is also used for rough and profiled floors.

Preparation / Conditioning For NEW Floor Pendulum Rubber Sliders

The ‘striking edge’ of the rubber slider is ‘conditioned’ or ‘prepared’ before use to ensure consistent results always occur. The conditioning places a small flat chamfer on the trailing edge of the rubber slider.

Two hard FLAT surface plates (A & B) such as plate glass or non-flexing sheet steel are set up with 2 different abrasive surfaces of waterproof abrasive paper (A) and lapping paper (B); each paper type secured to the surfaces by tape or in an appropriate test jig (Contact FloorSlip to buy your Floor Testing Equipment). The sheets will be of sufficient size to allow a minimum of 127 mm of swept area. Each plate (A & B) is secured to the test bench or into a test jig.

Preparation / Conditioning For NEW Floor Pendulum Rubber Sliders

Plate A + New Sheet of P400 grade silicon carbide abrasive paper

- Set up the footpint distance using a gauge (as shown in the next section below)

- Swing the slider across DRY P400 paper 10 times

- Carefully remove any burr

- Reset the floor length gauge (footprint)

- Swing the slider DRY across the sandpaper another 10 times

- Carefully remove any burr

- Discard the P400 paper (or use a fresh part of the sheet for further conditioning)

Followed by:

Plate B + New Sheet of Pink Lapping Film 3M 261X Imperial TM Lapping Film Grade 3MIC’*

- Set up footpint distance using gauge (as shown in the next section below)

- Swing the slider across the WET Lapping film 20 times

- Carefully remove any burr

- Discard the Lapping paper (or use a fresh part of the sheet for further conditioning) Preparation / Conditioning For WORN Floor Pendulum Rubber Sliders

Preparation / Conditioning For WORN Floor Pendulum Rubber Sliders

Plate A + New Sheet of P400 grade silicon carbide abrasive paper

- Set up the footpint distance using the gauge (as shown on the image below)

- Swing the slider across DRY P400 paper 3 times ONLY

- Carefully remove any burr

- Discard the P400 paper (or use a fresh part of the sheet for further conditioning)

Followed by:

Plate B + New Sheet of Pink Lapping Film 3M 261X Imperial TM Lapping Film Grade 3MIC’*

- Set up footpint distance using gauge (as shown on the image below)

- Swing the slider across the WET Lapping film 20 times

- Carefully remove any burr

- Discard the Lapping paper (or use a fresh part of the sheet for further conditioning)

*Google the search term ‘261X 3 MIC’ to find suppliers

IMPORTANT – Discarding of Worn Sliders

Read more aboute Rubber Slider Life

BS-EN-16165 limits the maximum amount of wear on the ‘striking edge’ of slider #57 / #55 to 2.5mm and slider #96 at 4.0 mm. (The minimum is 1.0 mm). It has been verbally indicated by the UKSRG (though not mentioned in EN-16165) that once slider #57 / #55 has worn to 2.5mm, that Pendulum Test Values using slider #57 / #55 may be innacurate due to the mechanics of how the softer rubber of #57 / #55 interacts with the floor (as opposed to the harder rubber slider #96) hence the reasoning for limiting the wear to 2.5mm on #57 / #55 sliders.

Pre-Use Verification activities

Immediately prior to test, the correct operation of the Pendulum Test Equipment is achieved through Verification by using the sliders (#57/#55 and #96) on 3 different testing mediums. The table below shows the expected results with the tolerances throughout for #96 Sliders of +/-2 and #57/#55 Sliders of +/- 3. PTV.

PVS = Pendulum Verification Surface

- PVS#1 – Float Glass Test 1 – 0 to 15 PTV

- PVS#2 – Pavigres Tile Test 2 – 25 to 40 PTV

- PVS #3 – Pink Lapping Film 3M: 261X 3 MIC (Matt Side) – 50 to 75 PTV

- PVS for Green Lapping Film is no longer part of this standard.

Conducting the Pendulum Test

Temperature Conditions – Off Site Floor Sample Testing – The room temperature shall be maintained at (20 ± 5) °C for at 2 hours prior to the test and during of the test. On-Site, post setup, a 30-minute period should elapse to allow the equipment and sliders to settle to the ambient on-site temperature. this is not always particularly practical for multiple location tests or when time is limited due to customer pressure and the costs for attendance by Slip Injury Lawyers.

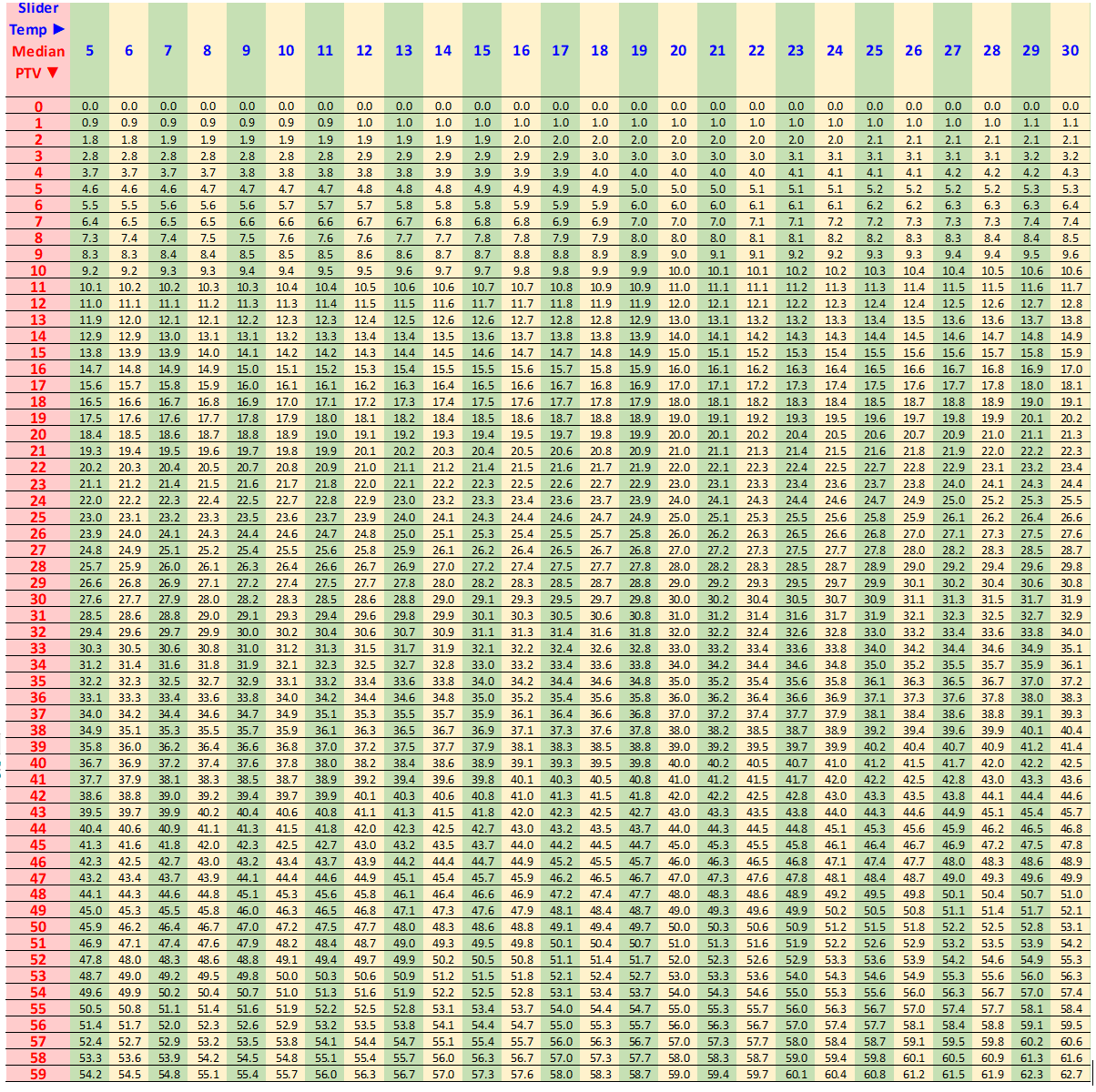

Adjustment for 55/57 Slider Temperatures – Unlike the simple table used in BS-7976-2 to adjust for final target values for temperature adjustments using the 55 slider, EN-16165 uses a very complex mathematical formula ‘C1’ (EN-16165- section C.5.3 refers) to determine the new ‘Target’ value for rubber slider 57/55 for ‘PTV adjustments corrected to 20° C.

The formula states the Corrected Value = Median PTV Result divided by (1 – (0.0059 x (slider temperature recorded – 20)). E.g., 16 Median PTV at 13°C = 16 / (1 – (0.0059 x (13-20)) ► 16 / 1- - 0.0413 ► 16 / 1.0413 = 15.365 (15.4 on the table and rounded to 15 PTV i.a.w. EN-16165 C.5.3).

Image - Look Up Table for Slider 57 Temperature Correction

FloorSlip have plugged the 'C1' formula into a spreadsheet and arrived at the following look-up table. The matrix to determine the new value is based on the Slider Temperature recorded (Top Row) and Median PTV (Left Column) recorded for the #57/55 slider. Use the formula for values outside of these ranges

Floor Test Directions, Quantity of Tests and Order of Tests - BS-EN-16165 is not particularly specific about this (this was also a problem with BS-7976-2). Therefore:

STRONG SUGGESTION – follow the procedures in UKSRG guidelines at latest issue ( for a ‘sensible approach’ to the order, quantity and directions of test. The UKSRG guidelines are a very comprehensive addition to both superseded BS-7976-2 and current BS-EN-16165; they are fully supported by the UK HSE and recognised by floor testers and UK Courts in Slip Injury Claims

Test Directions – Isotropic Floors - Under BS-EN-16165, ‘isotropic’ floors (floors showing the same test values when measured in different directions on that floor type) may be limited to single tests in one direction post the initial checking in 3 directions (0, 45 and 90 degrees) to confirm the isotropic state

Test Directions – Testing in the 180 degrees direction - Some product specifications (and some other Test Standards other than BS-7976-2 and BS-EN-16165) require testing at 180° to the original direction as well as the 0°, 45° and 90° normally carried out. FloorSlip also find that testing at 180° on natural wooden surfaces is particularly necessary due to the grain.

Setting the FootPrint Length – The pendulum arm / slider set upon the floor at a precisley measured length of 124mm +/- 1mm using a 7mm thick gauge as the image below shows giving an actual sliding length of 126mm. This value has not changed from BS-7976-2 but is described differently and better in BS-EN-16165 as using the back plate of the slider is far more accurate than attempting to use the corner of the rubber slider, which will change dimensions as it wears.

The Differences Between PENDULUM TESTS BS-7976-2 (Predecessor) and BS-EN-16165 ANNEX C (Successor)

♦ DIFFERENCE POINT 1: FLOOR SURFACES THAT CAN BE TESTED

BS-EN-16165 is specified for pedestrian surfaces only*

BS-7976-2 was designed for pedestrian surfaces and roads.

*For other than pedestrian surfaces use BS-EN-13036-4:2011 for Road and Airfields traffic Pendulum testing or BS-EN-16165. BS-EN-13036-4:2011 was issued to supplement now superseded BS-7976-2 and is not instead of BS-7976-2.

♦ DIFFERENCE POINT 2: RUBBER SLIDERS

BS-EN-16165 (Annex C) – Calls up Rubber Sliders #96 and #57.

BS-7976-2 - Calls up Rubber Slider #96 (Also referred to as 4S or (Standard Shoe Sole Simulating) and slider #55 (Also referred to as TRL or Transport Road Laboratories).

♦ DIFFERENCE POINT 3: 'ISOTROPIC’ FLOORS

EN-16165 (At section C-5-1) - Isotropic floors (floors showing the same test values when measured in different directions on that floor type) may be limited to single tests in one direction post the initial checking in 3 directions to confirm the isotropic state (0, 45 and 90 degrees).

BS-7976-2 – Does not quantify data for Isotropic Floors

♦ DIFFERENCE POINT 4: QUANTITY OF FLOOR TESTS

BS-EN-16165 (At Section C-5-1) The spec simply informs about WET tests, DRY tests and AS FOUND Tests. But is not well written in respect to the order of testing (As found, Dry, then Wet Test); the quantity of tests; or the direction of tests; It also references out to say some other tests may require 180-degree tests to the original direction but fails to elaborate on which. See our Page on Multiple Floor Surfaces Tests, which may describe what you are looking for

BS-7976-2 (At Annex B) is also not well written discussing sampling but also fails to inform on order of test, direction and quantity.

STRONG SUGGESTION – follow the procedures in UKSRG guidelines for a ‘sensible approach’ to the order, quantity and directions of test. The UKSRG guidelines Issue 5 and 6 were written as comprehensive addition to both BS-7976-2 (at issue 5) and EN-16165 (at issue 6); they are fully supported by the UK HSE and recognised by floor testers and UK Courts in England, Scotland and Wales by Lawyers and Judges in Slip Injury Claims

♦ DIFFERENCE POINT 5: DECLARATION

BS-EN-16165 (Annex C) - Where a test is conducted, test reports are to indicate ‘Pendulum Testing conforms to BS-EN-16165 Annex C’

BS-7976-2 (At Section 7) - Where a test is conducted, test reports are to indicate ‘Pendulum Testing conforms to BS-7976-2: 2002 + 2013. As BS-7976-2 is now superseded, this is unlikely to be relevant anymore.

♦ DIFFERENCE POINT 6: VERIFICATION VALUES

BS-EN-16165 (Section C4) - For sliders 57 and 96, verification values have changed for the Float Glass, Pavigres Tile and Pink Lapping film; the quantity of swings has also changed.

See ‘Preparation / Conditioning For WORN Floor Pendulum Rubber Sliders’ in the section above

(Pendulum Verification Surface = PVS)

- PVS Float Glass Test 1 – 0 to 15 PTV

- PVS Pavigres Tile Test 2 – 25 to 40 PTV

- PVS Pink Lapping Film 3M: 261X 3MIC (Matt Side)* – 50 to 75 PTV

- PVS Green Lapping Film is no longer part of this standard.

*3M 261X Imperial® Lapping Film Grade 3MIC is a trade mark owned by 3M United Kingdom and is the trade name of that product.

BS-7976-2 (Section 8 Table 2) - This standard calls this topic Validation as opposed to Verification. The validation/verification values for ‘4S’ (#96) rubber and TRL (#55) rubber slider are different to BS-EN-16165; consult BS-7976-2 for details

♦ DIFFERENCE POINT 7: STRIKING EDGE WIDTH

BS-EN-16165 (Section C.2.1.2.16) - The striking edge dimensions of the slider rubbers are:

- Slider 55 / 57 – Minimum 1.0 mm to maximum 2.5mm

- Slider 96 – Minimum 1.0 mm to maximum 4.0mm

BS-7976-2 (Section 5.2.2.3) Wear of 4.0 mm on all sliders including 55 (TRL) and 96 (4S).

♦ DIFFERENCE POINT 8: TEMPERATURE CONSTRAINTS IN BENCH / SITE TESTING

BS-EN-16165 (Section C-5-1) There is an expectation that: -

- Off Site - room temperature shall be controlled at (20 ± 5) °C for at least 2 hours before the test begins and for the duration of the test

- On-Site - post setup on site, a 30-minute period will elapse to allow the equipment / sliders to settle to the ambient temperatures. (Unfortunately, this is not particularly practical when multiple locations are being tested or the time on site is highly limited due to customer constraints or attendance by Slip Injury Lawyers).

BS-7976-2. Not mentioned in BS-7976-2

♦ DIFFERENCE POINT 9: ADJUSTMENT FOR 55/57 SLIDER TEMPERATURES

BS-EN-16165 (Section C.5.3). A formula ‘C1’ is used (section C.5.3) to determine the new ‘Target’ value for rubber slider 57 for ‘PTV adjustments corrected to 20° C. The formula states the Corrected Value = Median PTV Result divided by (1 – (0.0059 x (slider temperature recorded – 20)). E.g., 16 Median PTV at 13°C = 16 / (1 – (0.0059 x (13-20)) ► 16 / 1- - 0.0413 ► 16 / 1.0413 = 15.365 (15.4 on the table and rounded to 15 PTV i.a.w. BS-EN-16165 C.5.3).

BS-7976-2 – (Section 6.3.2. Table 1) There was a simple table to adjust for final target values for temperature adjustments using the 55 slider.

♦ DIFFERENCE POINT 10: Setting the FootPrint Length

- BS-EN-16165 - Slider length at top face of 124 +/- 1mm giving a slider length of 126mm. The pendulum arm / slider set upon the floor at a precisley measured length of 124mm +/- 1mm using a 7mm thick gauge as the image below shows giving an actual sliding length of 126mm. This value has not changed from BS-7976-2 but is described differently. Using the back plate of the slider is far more accurate than attempting to use the corner of the rubber slider, which will change dimensions as it wears.

- BS-7976-2 - describes - Slider length between 125 and 127mm

♦ DIFFERENCE POINT 11: SLIDER LIFE

BS-EN-16165 (Section C.2.1.2.13) Slider assemblies shall be discarded 24 month after the certificate date

BS-7976-2 (Section 9 and Table 2) Slider assemblies shall be discarded 12 months after the certificate date unless than can meet clause 8 of BS-7976-2 and results fall outside of Table 2

Read more aboute Rubber Slider Life

♦ DIFFERENCE POINT 12: SLIDER STORAGE TEMPERATURE

BS-EN-16165 (Section C.2.1.2.13) For long time slider storage, keep the sliders in the dark and at a temperature below 10 °C.

BS-7976-2 (Section 9) Sliders should be stored in the dark between 15 and 25 Degree Centigrade.

BS-EN-16165 – Annex D – TRIBOMETER TEST

Overview – The Tribometer never formed part of BS-7976-2 and has been introduced in BS-EN-16165. The Tribometer is not often used in the UK but is more so in Europe and in the USA under ANSI Standards. It is sometimes referred to as the 'Sled Test'

The Tribometer is a device of a set weight (10.0 kg +/- 0.1), which acts upon a small rubber of a shore hardness of 50 +/-3 hardness (wet / dry tests) and leather slider of 60 (+/- 10) hardness (dry tests) mounted beneath the test equipment acting upon the floor surface.

The wet test does not use plain tap water but instead a solution of 0.1 % sodium lauryl sulphate (purity ≥ 99 %) in deionised or distilled water. The solution must stay on the surface for 5 minutes before testing (making multiple tests a very lengthy engagement).

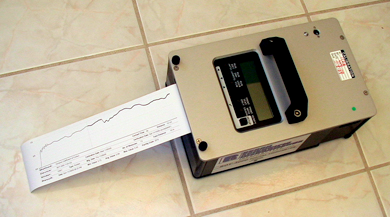

A manual Tribometer is pulled at a steady rate (0.2 to 0.25 m/s) and over a specific distance (minimum 0.5 m) using a spring balance to give the correct rate of travel. A motorised electronic Tribometer removes the need for manual intervention except to press the ‘Go’ button.

The equipment and slider are verified for use beforehand using test samples. The sliders are also conditioned for use using abrasive papers

The results of sliding friction coefficient (μ) are printed out or may be transferred electronically on more expensive devices.