Format of the Floor Test Results

There are 3 types of Floor Slip Resistance Testing Values

1. FLOOR PENDULUM TEST VALUES (PTV)

The floor Pendulum Test Equipment can be used for Pedestrian and Vehicular Traffic and regardless if you have On Site Floor / Road Pendulum Testing or (Off-Site) Floor Sample Pendulum Testing, the test results are the same.

The Test produces a value known as the Pendulum Test Value or ‘PTV’.

PTV is less commonly referred to as the Slip Resistance Value (SRV) and in America, the British Pendulum Number (BPN) where the Pendulum Test Equipment is known as the British Pendulum Tester.

Floor Pendulum Test Equipment (Pendulum shown swung to get result)

Pendulum Test Value of 65PTV showing (Equals Coefficient of Friction of 0.65)

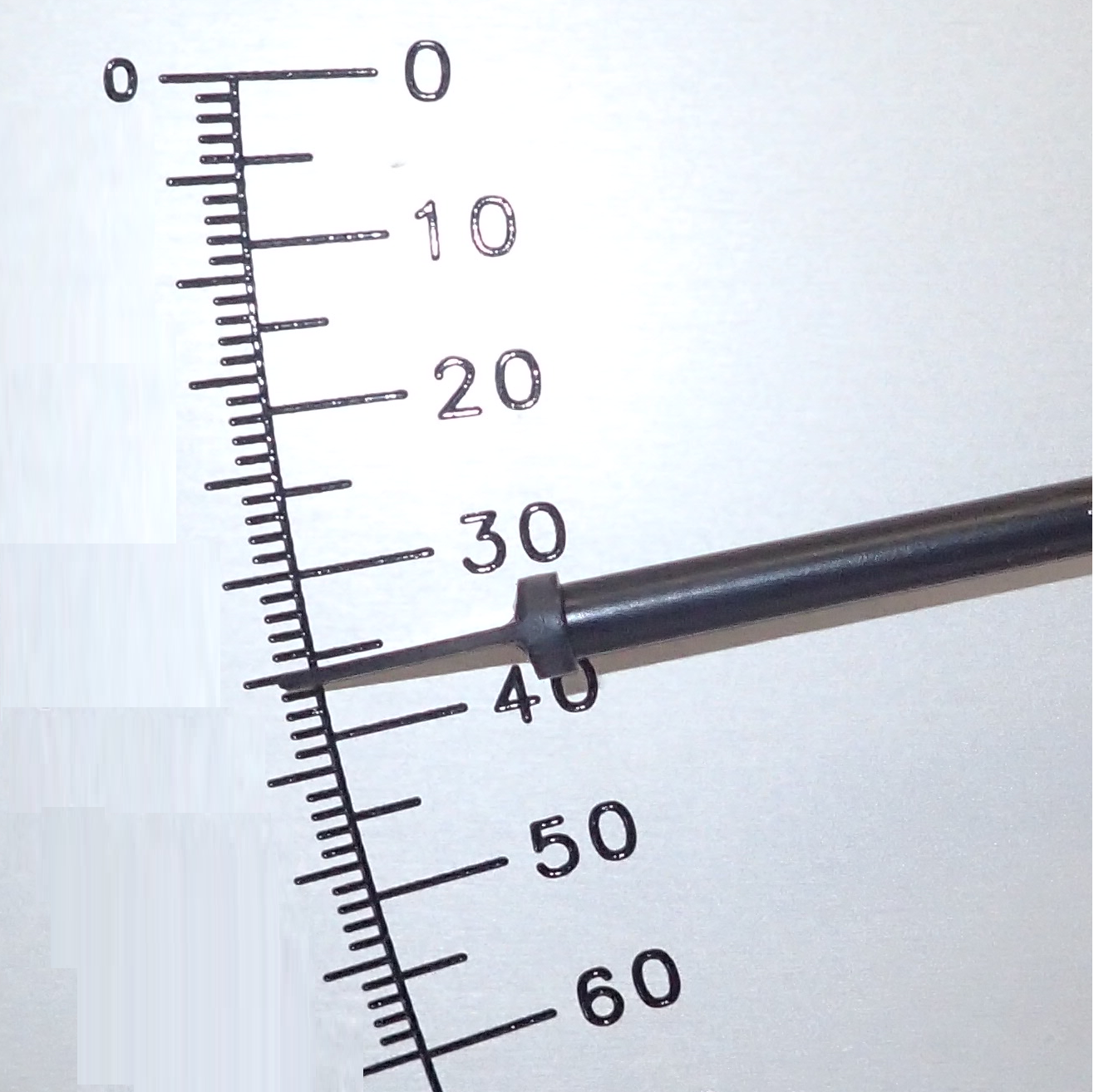

Relation of PTV to Coefficient of Friction (CoF)

The CoF is the frictional force, which presses two surfaces together. It can be measured by the Pendulum Test. The Pendulum Test Value (PTV) is the...measurement of Coefficient of Friction (CoF) divided by 100.

For example, 36 PTV / 100 = 0.36 CoF (Conversely, 0.36 CoF x 100 = 36PTV).

Pendulum Test Value of 36PTV (Equals Coefficient of Friction of 0.36)

What does the Pendulum Test Value (PTV) mean to me?

The UK government Health and Safety Executive (HSE) have determined: -

- A slip or fall on Wet or Contaminated Floor Surface will have a very high likelihood to cause a slip and fall and Probable Slip Injury.

- A test value of 36PTV or better (where 0 PTV is the worst value) when found on a Wet or Contaminated* horizontal surface (0 degrees of slope) will deliver a ‘Safe Floor Surface. It is critical that 36PTV is arrived at when WET or CONTAMINATED floors are tested; DRY floors always exceed 36 PTV so will fool you into thinking the floor is safe!

- The value of 36 PTV indicates an HSE Categorisation of ‘Low Slip Potential’, equating to a ‘Frequency (probability) of Slip’ of just 1 in 1 million.

- Even the slightest amount of water or contaminant will sharply reduce results to a very inadequate value.

Just a small amount of liquid will cause Floor Slips

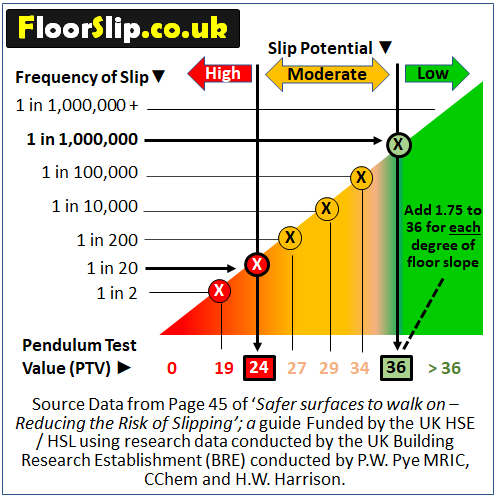

Categories of Slip Potential & Probability of Slip

There are 3 Categories of ‘Slip Potential’ each having a related 'Frequency (probability) of Slip'

- A Low Slip Potential (HSE recommended)

- A Moderate Slip Potential

- A High Slip Potential

The image below portrays the values of Slip Potential and Frequency of Slip based on the Pendulum Test Values arrived at during Floor Testing.

Note that below 36 PTV the values drop off very quickly, the scale is NOT linear; a floor of 19 PTV has a 1 in 2 chance of slip!! See Probability of Slip

Floor Slip Potential and Frequency of Slipping

My Floor Cannot Achieve 36 PTV. What Now?

There are a number of options from changing flooring to Floor Coatings or demonstrating that ALARP can be met.

ALARP means 'As Low As Reasonably Practicable' and is the task of consistently and effectively proving that a floor can remain safe in nearly all circumstances and that transgressions can be quickly, easily and repeatedly dealt with

Also read more at the section Buying New Floors

Different PTV Values for Different Surfaces

The UK HSE have specified that 36PTV delivers a 'Low Slip Potential'. However, there are many authorities such as councils and large businesses like British Rail who expect far higher Pendulum Test Values, particularly in outside environments.

UK Roads and pavements are generally found to be specificied higher than 36 PTV. The higher values allow for more extreme environmental conditions and allow for wear of the road surfaces, particularly problematical for high traffic use surfaces.

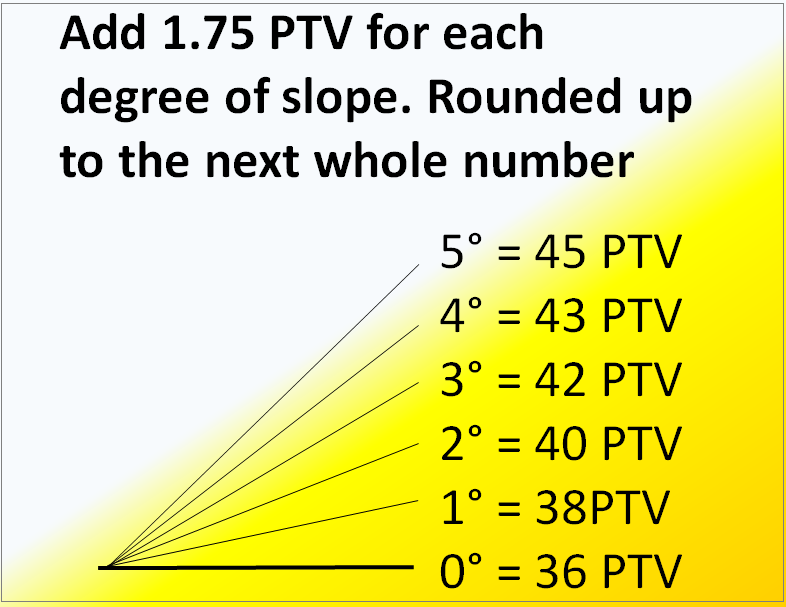

The Effects of Slopes on the Pendulum Test Value

We all know that a slope is more slippery than a level surface and the more slippery the surface, the easier it is to fall.

In normal circumstances a floor with a WET or CONTAMINATED Floor Pendulum Test Value of 36 PTV on a horizontal surface is satisfactory to provide a Floor Surface Legally Deemed as Safe.

However, on any Floor Slope, the ‘Target PTV’ of 36 must be increased by 100 x tangent of the angle. Put simply, add 1.75 PTV for every 1 degree of slope and round UP to the next whole number where any fraction exists. Read more about Floor Slopes.

Increasing the Target PTV on Floor Slopes

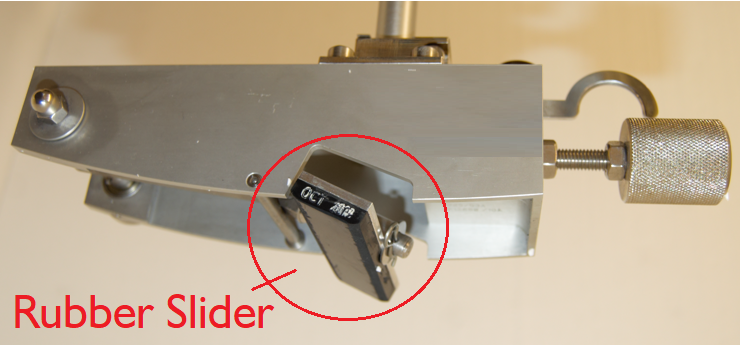

Pendulum Rubber Sliders Test Results

In the UK, the Pendulum Test is performed with ‘Rubber Sliders’ of 2 different hardness values (#55 and #96).

Depending on several different conditions an On-Site Floor Pendulum Test or Off-Site Floor Sample Test might be performed with one or both of the sliders.

The test result that delivers the LOWEST value is always the one selected at the final test results. Read more about Rubber Sliders and when they are selected

Rubber Slider on the Foot of the Floor Pendulum Test Equipment

2. SURFACE ROUGHNESS TESTING VALUES

A floor with a rougher surface generally provides better traction.

Surface Roughness Testing is used to determine the ‘level of floor roughness’; particularly important where any Floor Is Likely to Become Contaminated from WET or DRY CONTAMINANTS. For example – water, diesel, tomato ketchup, grapes, fish guts, cooking oil or Perfume; or DRY Contaminants like swarf or sawdust or talcum powder.

The Surface Roughness Test checks provides a microscopic level evaluation to arrive at a Surface Roughness Test Value known as the ‘Rz Value’ or ‘µm value’.

Ideally the Pendulum Test Value and the Rz Value will compliment each other, i.e., the rougher the floor surface, the higher the Pendulum Test figure ‘should be’, however, the Rz value and the PTV values do not always relate. In that instance, the Pendulum Test Value will always take preference over Rz as it genuinely imitates heel-slip.

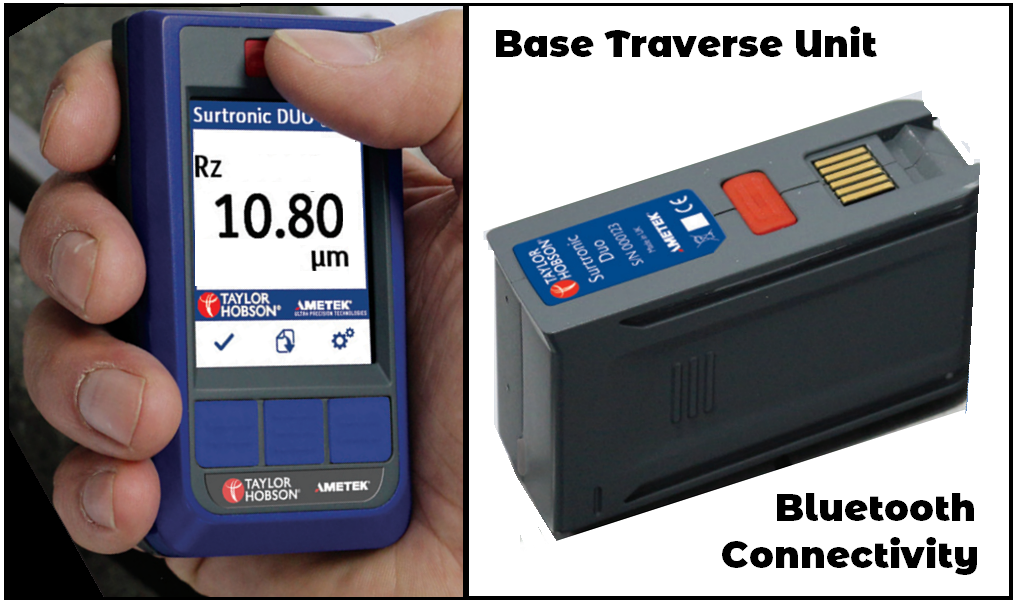

Surtonic Duo - 9 Surface Roughness Tester

Surtonic Duo - 2 Surface Roughness Tester

The Surface Roughness Test Results

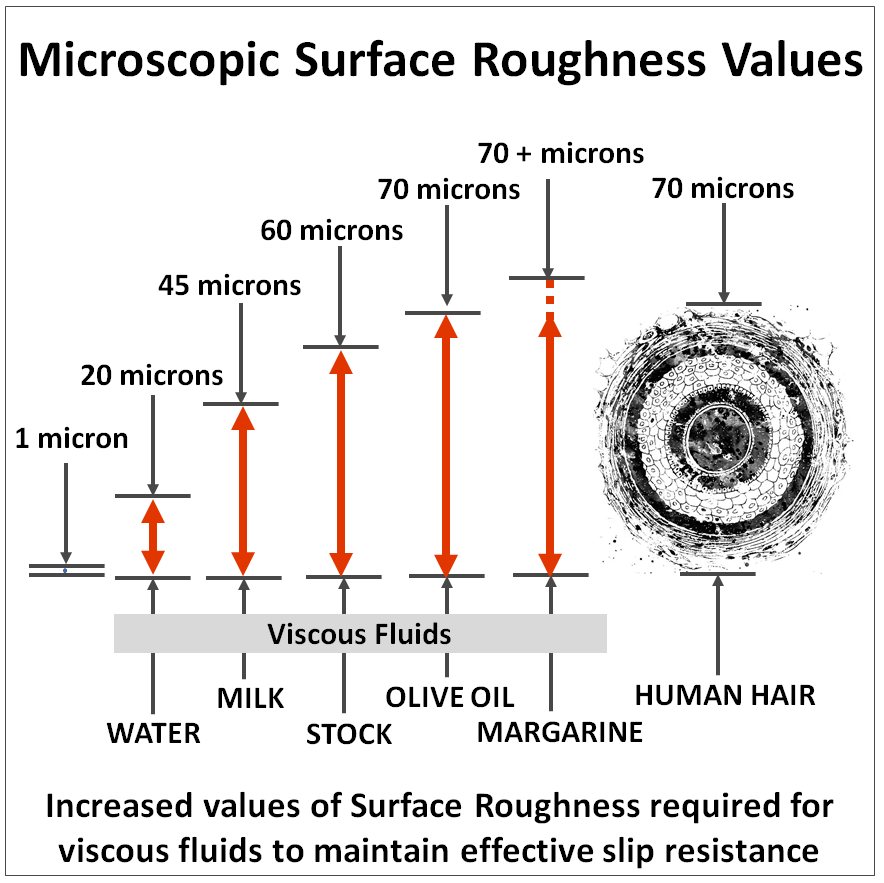

If a floor is likely to become ‘Water Wet’ regularly or through repeated spills and drips, then ideally, a floor should provide a minimum Rz of 20µm (micrometres) and higher values if thicker liquids (more viscous) are likely (The Image below best portrays this).

Note, the Surface Roughness Test Values should NOT be used as a standalone result...

An On-Site Floor Pendulum Test should always be conducted FIRST to determine the true Slip Resistance Potential with Surface roughness Testing conducted in conjunction to determine the realtionship between the PTV and Rz results as anomalies often exist.

Thereafter, once a baseline PTV has been established with the Pendulum Floor Testing, Surface Roughness Testing can be conducted (e.g., every 3 months) to Monitor for Floor Wear. This is particularly important on softer floor surfaces like vinyl, linoleum and wood and even concrete where high footfall or vehicular traffic occurs will wear. But far less likely to see wear on harder surfaces like marble or terrazzo or porcelain.

Rz (µm) Surface Roughness Values to aim at

3. RAMP TESTING VALUES

Ramp Testing of a floor surface provides values of slip resistance known as ABC Ratings (Bare foot) and R-Ratings (Shod Feet)

Ramp Testing is performed using a floor sample affixed to an adjustable ramp, which is tipped up to various angles whilst a person is carefully walking / shuffling backwards and forwards on that floor until they slip. The person might be barefoot or shod and various contaminants will be sprayed onto the floor surface, the contaminants depending upon the Customer's work place.

The Ramp Test increases the angle until a person slips

The angle that the person slips determines the Rating.

An ABC rating will be arrived at - If the test subject (person) is barefoot, water is normally sprayed as the contaminant as this is a typical test for predominantly wet areas. The values are: -

- A – Most Slippery (Small Ramp Angle)

- B – Less Slippery

- C – Least Slippery (Largest Ramp Angle)

An R-Rating will be arrived at if the test subject (person) is shod where many contaminants might be used such as motor oil, but will more likely to be a contaminant relevant to the location where the floor will be fitted. The values are: -

- R9 Most Slippery (Small Ramp Angle)

- R10

- R11

- R12

- To R13 Least slippery (Largest Ramp Angle)

There is some ‘loose correlation’ between Pendulum Test Values and R Ratings but the data is too wide a range to be useful or relied upon. If you need a Pendulum Test Value, then have a Floor Sample Pendulum Test carried out to arrive at the PTV; If you need an R Value, then have a Ramp Test carried out followed by a Pendulum Test.

But Do NOT attempt to read across the PTV results to the R-Ratings

Many floor specifiers and flooring outlets try to tell you that R values can be used to specify floors; they should not be used. R Values are for Specific floors, in specific environments wearing specific shoe sole and heel rubber types and profiles. They are not for Generic Use. Read more in our section ‘Buying New Floors’. If you are forced down this route, always aim at R12 or R13 and have the flooring Floor Sample Tested before laying.

Contact FloorSlip Today to discuss your options.