20 Top Tips on Specifying and Buying Safe Floors

Data for Architects, Builders, Councils and private individuals etc. Specifying Safe Floors.

If you have any questions try the FAQ's or Contact FloorSlip and we can talk to you about your particular scenarios of Floor Safety.

THE STEPS TO BUYING 'SAFE FLOORS'...

STEP 1 – Determine Requirements

In each flooring area of the project, create a table of: -

- The functional purpose of the floor - e.g., Kitchen or Gym or Warehouse

- The Type and Amount of Floor Contamination that will occur at each room or area - e.g., rain ingress; or spills from food, drink, oil, perfumes or talcum powder.

- The aesthetic expectation of the floor surface - e.g., Concrete or Tiles or Wood.

Rule of Thumb - Matte finish and profiles surfaced floors are far safer than shiny floors. You and your Customers have a Legal Obligation to Provide Safe Floors

STEP 2 – Research Floor Types Available

Using the table created in Step 1 of Buying Safe Floors, research the floors available that will meet the requirements. Consider if each floor surface and accompanying features such as handrails, Floor Slopes, lighting, adjacent floors of vastly dissimilar floor slip values (PTV*) will: -

- Meet Floor Safety Legal Requirements

- Meet UK Building Regulations - Principally Part K and Part M to Prevent Floor Slips.

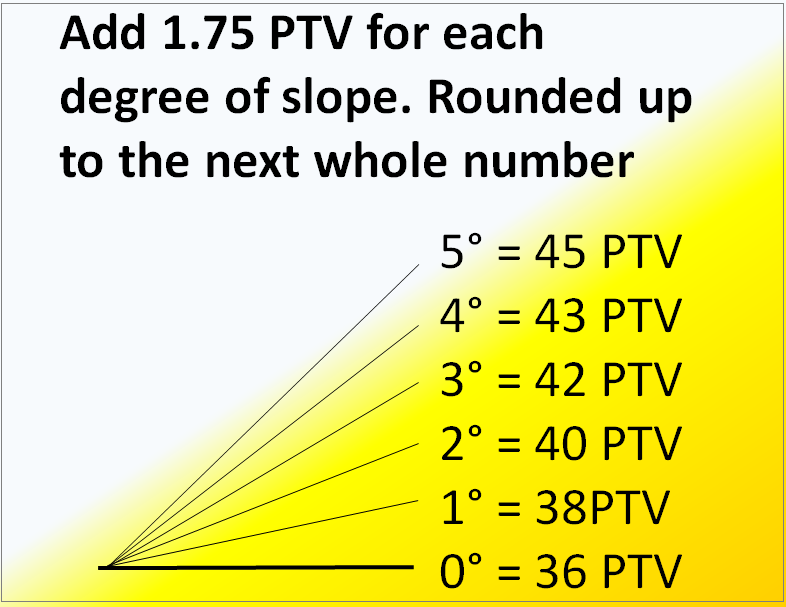

- Achieve the required Floor Pendulum Test Values (PTV) You are specifically interested in the WET / CONTAMINATED floor test Values. Aim at a TARGET of 36 PTV* when WET TESTED on a horizontal surface adding 1.75 PTV for Each Degree of Floor Slope above 0° **

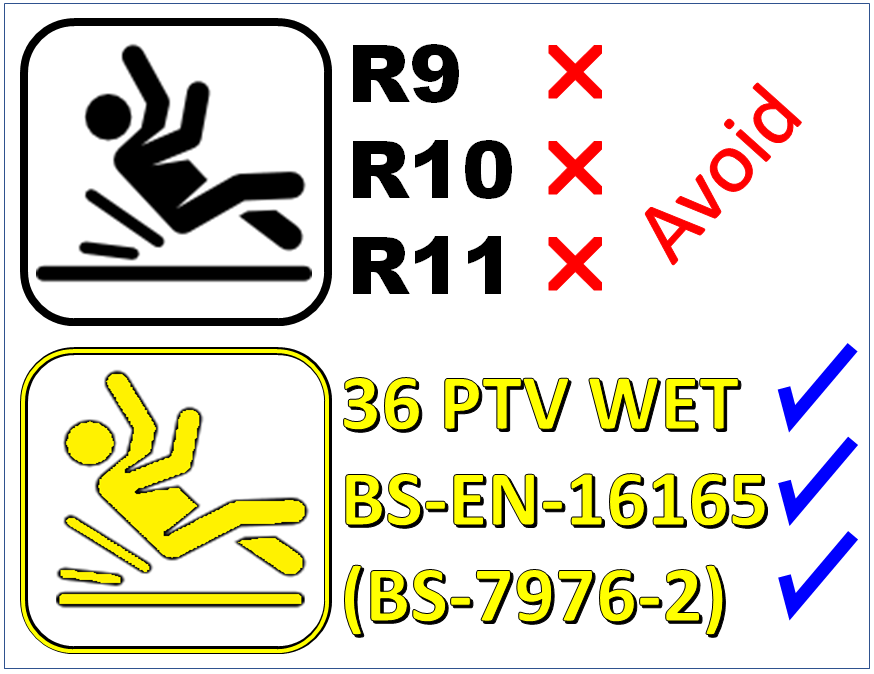

Important Note - Do NOT use Floor R-Ratings unless a specific floor will have specific floor/boot/oil combinations (e.g., in a laboratory where footwear can be controlled). R-Ratings are NOT FOR GENERIC FLOOR SPECIFYING and there is NO Direct Read Across from PTV to R-Ratings as often publicised.

*PTV = The Pendulum Test Value in Pendulum Testing

**For example: a floor with a 4-degree slope would require 36 + (4 x 1.75) = TARGET of 43 PTV.

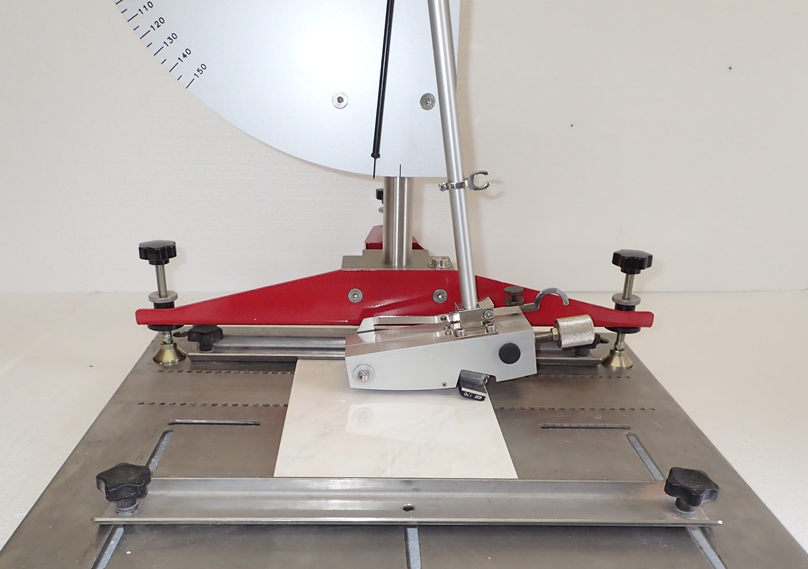

STEP 3 – Pendulum Test Floors To Determine Slip Resistance Values

In STEP 2 above, you will probably have used internet data to find the specifications.

However, we have often found when compiling Expert Witness Reports that internet data is quite often incorrect about floor specification and test data.

We strongly suggest: -

- Definitely - Spend a little money NOW to get Floor Samples Pendulum Tested to EN-16165. This will Accurately Verify if the floor is fit for purpose and give you a complete portfolio of verified data, which is needed in todays Slip Injury Claim culture.

- Avoid the embarrassment and huge costs associated through changing incorrectly specified floors either at building handover or later when a Slip Injury Claim is made

- Consider Also - Getting first-fit in situ On-Site Floor Pendulum Testing before laying complete complexes with the flooring selected; floor samples tested may have changed radically in composition by the time the floors are laid.

Understanding The Floor Test Results

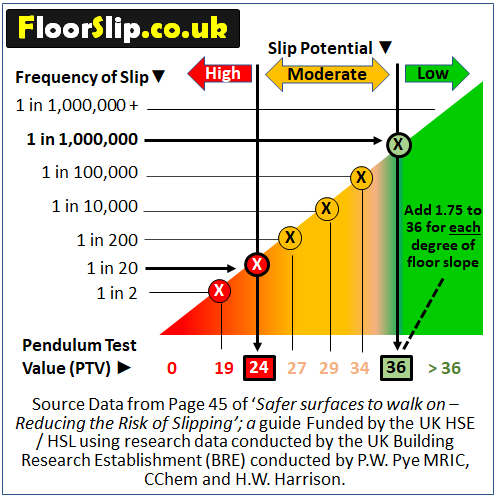

The Pendulum Test Equipment Values can be used to determine: -

The UK HSE Recommend a ‘LOW SLIP POTENTIAL’ which equates to 36PTV on a horizontal wet tested floor and a minimum ‘FREQUENCY OF SLIP’ of 1 in 1 million.

The graph below simply portrays this. Where values can NOT be met, then ALARP may apply.

Graph of Values for FREQUENCY OF SLIP on a Horizontal Surface

Further Data in Respect to Buying and Specifying Floors

1. DRY, CLEAN FLOORS VERSUS WET / CONTAMINATED FLOORS

Dry Clean floors rarely cause Slips. Slips occur when the normally dry floor becomes wet or the floor becomes contaminated with substances relevant to that environment (e.g., beer at a bar or oil in a kitchen). Between the UK HSE and Floor Testing Standard EN-16165, it has been estimated 90 to 95% of slips occur on Wet and Contaminated floor surface and one third of injuries in the UK are from slips, trips and falls; some very serious arriving at Slip Injury Claims.

It only takes a small amount of liquid or other wet and dry floor contaminants to cause floor slips such as a grape, banana, ice-cream, peas, custard, tomato sauce, perfume, talcum powder, sawdust

2. DRY CONTAMINANTS

Dry Floor Contaminants are as big a problem as wet floor contaminates and can markedly reduce the slip resistance of the floor surface. Examples include the Talcum Powder, Foot Powders, at a Gym; or wood and plastic shavings, salt and even sand in some cases.

3. WET FLOOR EVIRONMENTS

If the floor will nearly always be wet like Jacuzzi, swimming pool, hotel bathrooms, gym showers, then ALWAYS aim at a ‘Low Slip Potential’ floor. Or aim at a floor with a C Rating surface, but even then, ALWAYS GET FLOOR SAMPLES TESTED BEFORE COMMITTING TO LARGE OUTLAYS

4. BATHROOMS

Baths, showers trays, bathroom floors, splashes from sinks cause many slips and a big problem for hotels, these can also be Pendulum Tested On-Site or at the suppliers. Try to also add ergonomically placed securely mounted grab handles as well.

5. FLOOR TYPES

As a ‘rule of thumb’ only, matte floors tend to be safer than shiny floors in most cases when wet or contaminated. Notoriously slippery floors are surfaces like Terrazzo and Ceramics. However, modern composite floors are sometimes proving the exception than the rule.

We always Recommend getting Floor Samples Tested or having On-Site Floor Pendulum Tests BEFORE specifying or laying floors.

6. AESTHETICS & SLIP INJURY CLAIMS

Try to effectively convince Customers that 'Pretty Floors' do not always equate to Safe Floors. FloorSlip conduct many Expert Witness Cases and it is common to see people Making Slip Injury Accident Claims of £50,000 as the norm; be very aware that claims can possibly pass back to floor specifiers as well as managers, owners and landlords.

7. HAND RAILS

UK Building Regulations are specific about correct hand rails. Approx. 50mm in diameter, easy to grip, warm to the touch (like wood as opposed to metal), with the ability to easily wrap the hand around.

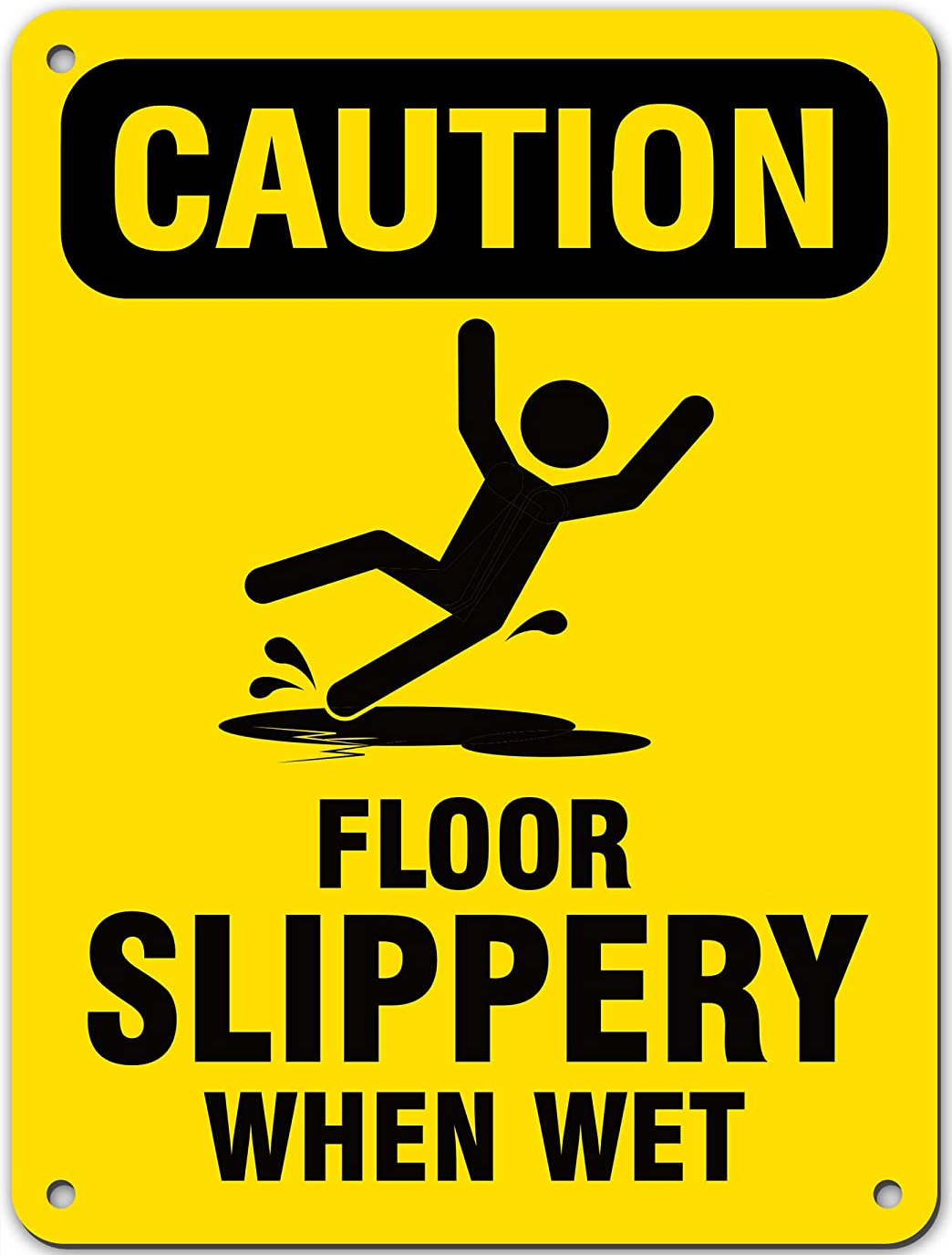

8. WARNING SIGNS

We would be rich if we had five pounds for every person in a Slip Injury Claim that said ‘but there were signs so they should NOT have slipped’. Warning signs such as ‘Wet Floor’ or ‘Slippery Floor’ should be used as the exception, not as the norm. For example, a customer drops a bottle of milk and it spills in a supermarket is the exception; but a wet floor in a changing room at a gym is the norm.

Think on it this way, adding a sign in the norm that the ‘Floor Will Be Slippery When Wet’ might be considered as admitting that it is known the floor is slippery but nothing has been done to correct it!

9. FLOOR SLOPES

For every 1 degree of floor slope a 5% increase in slip resistance is needed; this equates to 1.75 PTV (Pendulum Test Value). For example, a 3° Slope requires the baseline of 36PTV + 3 x 1.75 = 41.25 PTV rounded to the next highest value = 42 PTV

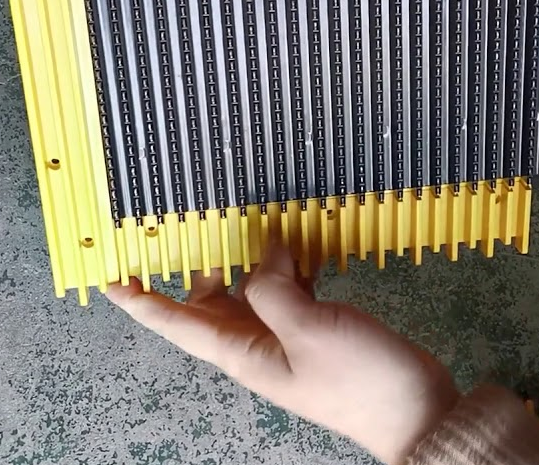

10. FLOOR ESCALATORS

Many escalators are made from aluminium with the grooves in the longitudinal directions; they can cause slips. Some manufacturers now coat with anti-slip solutions particularly at the leading edges (The nosings) and will ensure they offer High Visibility Step Nosings (which is also another law covered in the UK Building Regulations)

11. FLOOR ADVERTISING

A floor might start off with a decent non-slip surface then advertising slogans are laid as Vinyl’s on the floor. The Vinyl’s are sometimes advertised as ‘non-slip’ but will wear very quickly becoming slip hazards. Check the technical specs in respect to Pendulum Test Values; consider a schedule of Floor Wear Monitoring (every 2-3 months in high traffic areas) or FloorSlip can monitor for you.

12. FLOOR MARKINGS

Floor Markings like painted lines and demarcation areas unless applied with non-slip paints will cause floor slips. Ensure both the floor surface and the demarcation paint uses a non-slip paint proven to prevent slips. Consider a schedule of Floor Wear Monitoring using a Surface Roughness Test or get FloorSlip to do it for you on a regular basis. Contact FloorSlip Today

13. FLOOR ANTI-SLIP PAINTS

Paints, resins and coatings are often used to make floors aesthetically pleasing or maybe make floors easier to clean. However, only anti-slip products should be specified and subsequently correctly applied as per the spec sheets to be effective, many having aggregates in the mix which must be mixed correctly or high slip areas will occur.

All paints and coatings wear out and often become slippery and present a ‘polished’ appearance, so consider from the outsets a schedule of Floor Wear Checking using a Surface Roughness Test or get FloorSlip to do it for you. Contact FloorSlip Today

14. PRODUCTS ADVERTISED AS NON-SLIP

This is probably one of the biggest causes of misleading data and statements in Slip Injury Claims.

Companies advertises a floor as ‘non-slip’ and the statement is taken for granted but not verified through Floor Sample Testing. If it has specification sheet with BS-7976-2 or EN-16165 Floor Testing Standards at 36PTV or greater when the floor is WET, then it ‘may’ be OK (Ignore the DRY results; 99% of floors pass the Floor Pendulum Test when DRY).

For example, checker plate is not anti-slip with some shoes, even though it may appear that way. Smooth soled shows will slide across the top of the hard metal profiles and not grip effectively.

15. AVOID R RATINGS

We cannot stress this enough.

R-Ratings are for specific floors with specific footwear in a specific environment with specific contaminants (Motor Oil), conducted by a Ramp Test they should NOT be used for generic floor specification.

Unfortunately, the HSE in previous on-line data (since withdrawn) gave an incorrect impression that R-Ratings relate to Pendulum Test Values and a Read-Across from R-Rating to Pendulum Test Value could be applied – THIS IS INCORRECT. If you cannot get a spec sheet that quotes ‘36PTV when WET to EN-16165 (Or BS-7976-2 for old floor stocks)’ then get The Floor Sample Tested with Floorslip.

16. DOOR ENTRANCE MATTING

If mats are to be used, for example at door entrances, then they must be large enough to effectively soak away moisture before the person leaves the mat. Ideally, the base of the mat will allow the water to drain through into a drained recess under the mat. Be wary of rubber mats with all or some smooth surfaces, they can be slippery when wet. Purchase from suppliers who specialise in non-slip matting (as opposed to ‘non-slip’ advertised on E-Bay etc, unless they have a 36PTV Rating When WET). We can Floor Sample Test some mat types if required.

17. DISSIMILAR FLOOR SURFACES

Try to avoid large jumps of slip resistance values from one surface to the next; it is akin to stepping from firm ground to ice or vice versa and can cause slips and stumbles as a result.

18. FLOOR WEAR

Some softer Floor Surfaces wear very quickly like wood and vinyls. Be aware when you are specifying the floor surfaces that an additional tolerance has been considered to allow for wear; e.g., British Rail aim at least 40PTV and in some cases 44 PTV to compensate for floor wear. Note that floors can be monitored for wear

19. MOSS / ALGAE

Consider if the flooring is likely to become contaminated from moss/algae, which seriously causes slip resistance to fall. Moss/Algae quickly builds up on some materials and particularly if the floors are under or adjacent to bushes and trees.

20. FAQ's DO YOU HAVE ANY OTHER QUESTIONS?

Try the FAQ section on or Contact FloorSlip and we will hep you further.

.png)

.png)

.png)

.png)