Format of the Floor Test Certificates

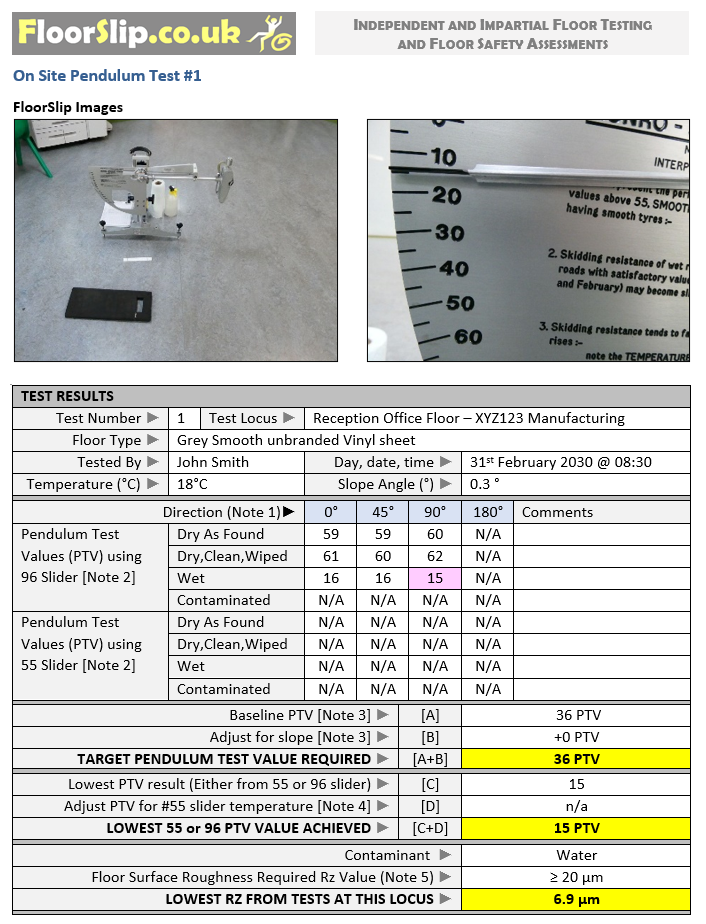

At FloorSlip, we have developed a number of different Floor Testing documents over the past 12 years for ease of use by Our Customers. One example below is the Floor Test Sheet we use for both regular On-Site Floor Pendulum Testing, Off-Site Floor Sample Testing and in Expert Witness Reports for Slip Injury Lawyers. Floor Testing is a complex topic and one with many nuances. We have made some notes to help you below these images, but if in doubt, simply Contact FloorSlip, all our FloorSlip Agents are well versed in the Topic of Floor Slip Resistance Testing.

Go to explanation of the Forms ▼

Explanation of the Floor Testing Forms

- The Floor Pendulum Test can be performed on pedestrian surfaces to emulate pedestrian walking or can be used upon road surfaces to emulate a vehicle skidding.

- The Pendulum Test Equipment is an established test equipment used and recognised by the UK HSE (Health and Safety Executive) for proving if a floor is safe or not.

- The Pendulum Test is also recognised in UK courts in Slip Injury Claims.

- The Pendulum Test is also recognised across the world; FloorSlip conduct Floor Sample Testing worldwide.

- The HSE in conjunction with its own laboratories, the Health and Safety Laboratories (HSL) have carried out over many decades proving of the test equipment and the methodology and arrived at parameters recognised across the UK. It has published hundreds of papers on the topic and it works in conjunction with other leading industries to develop safe floor and safe working practices including the (UKSRG) United Kingdom Slip Resistance Group and the likes of the UK Building Research Establishment.

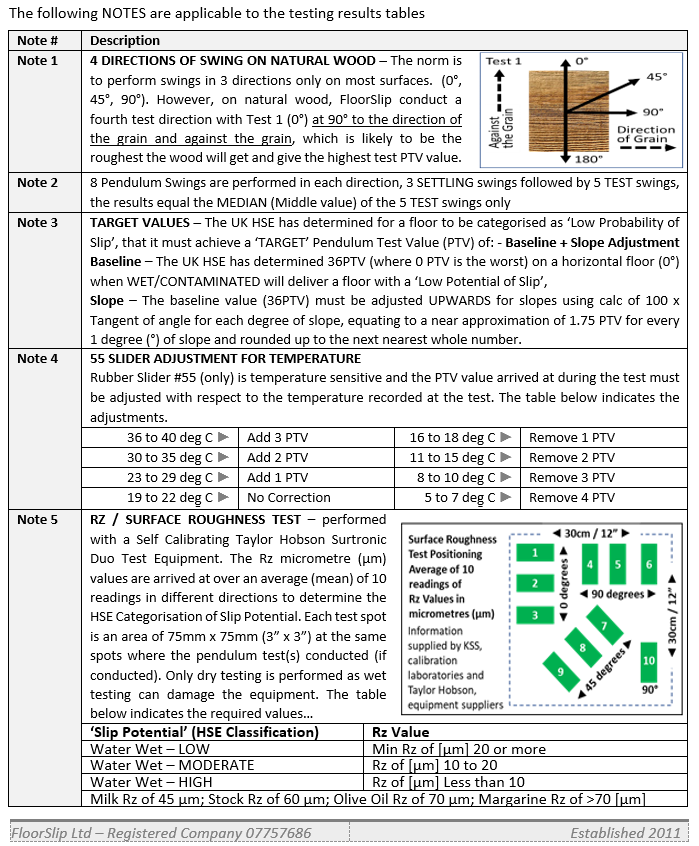

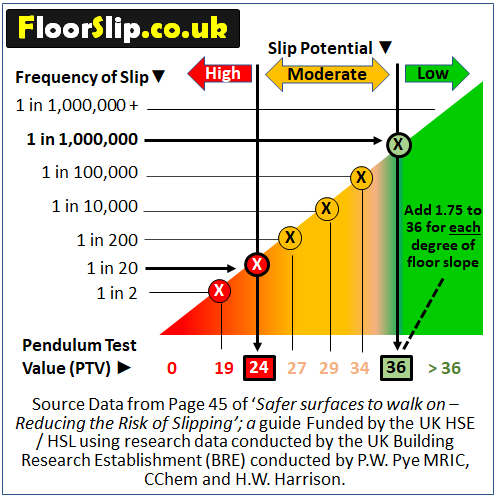

- The HSE/HSL have determined that a Pendulum Test Value (PTV) of 36 on a horizontal slope when the floor is tested WET or in a CONTAMINATED condition (with contaminants relevant to the environment) should provide a ‘safe floor’. The HSE/HSL having determined, for example, 90% of slips occur on wet / contaminated floors in the hospitality industry; the latest floor Testing Standard, EN-16165 quoting 95%. The Dry test rarely, if ever fails to meet 36 PTV. The value of zero PTV is the worst state. However, a very shiny floor will be as slippery dry when in combination with some smooth soled shoes (like walking on ice!)

- The HSE/HSL have also determined that a floor achieving 36 PTV can be categorised as a ‘Low Slip Potential’ and have a 'Frequency (probability) of Slip' evaluated as 1 in 1 million.

- Values less than 36 PTV also have categories of ‘Slip Potential’ and different values of ‘Frequency of Slip’, the image below simply displays this or use the link to see more detail..

Graph of 'Frequency (Probability) of Slip' and 'Slip Potential' in respect to Pendulum Test Values

- Where a floor cannot achieve a value of 36 PTV, then the ALARP principle might be applied (As low as Reasonably Practicable) where evidence must be provided to show how the floor remains safe; for example, by not getting a floor wet or by effective and fast acting Contamination Spill Control.

- The Pendulum Test is performed in accordance with UKSRG Guidelines and EN-16165 , which parallels / supersedes BS-7967-2 from Dec 2021 onwards. BS-EN-13036-4 is also employed specifically for roads and airfield runways.

- The Pendulum Test Equipment is built in the UK to EN-16165 (formerly BS-7976-) and precisely Calibrated Annually in accordance with EN-16165 mentioned above

- The Pendulum Rubber Sliders used and some of the calibration mediums are also subject to a 12-month expiry limitation. The sliders dictated in EN-16165 and BS-7976-2 and the UKSRG Guidelines when the test was performed are IRHD (International Rubber Hardness Degree) #55 or #57 (softer rubbers) and #96 (harder rubber).

- Slider #96 is typically used to emulate the shod environment.

- Slider #55 / #57 is typically used to emulate the barefoot environment and on profiled surfaces particularly where a surface is too rough / profiled to effectively use slider #96 as the harder rubber has a tendency to skip / judder on some surfaces affecting the outcome of the results.

- Where both sliders are used (55 and 96) for example in a swimming pool changing room where both bare foot and shod feet will be present, then it is always recommended to use the lowest value achieved as the final test result; the UKSRG Guidelines state also, on profiled surfaces. Using both 55 and 96 might help the user to understand the range of behaviours seen with different footwear (some footwear also has profiles soles / heels; some are smooth.). The UKSRG Guidelines also state profiled surfaces should also be tested with 55 and 96 sliders on the basis that profiles can give a wide range of slip resistance values.

- Slider #96 is not temperature sensitive but slider #55/57 are. Adjustments both up or down to the PTV values must occur depending upon the ambient temperature at the test location, the adjustments vary for different standards, read the section on Rubber Sliders

- Floor Slopes away from a horizontal surface will affect the ability to resist slips so the standards / guidelines inform an adjustment must occur. The mathematical calculation is the value 100 x tangent ‘a’ where ‘a’ is the slope angle. In more simplistic terms, a nominal nearly accurate value of 1.75 PTV (rounded up to the nearest integer) can be adjusted for each degree of slope.