Pendulum Rubber Slider

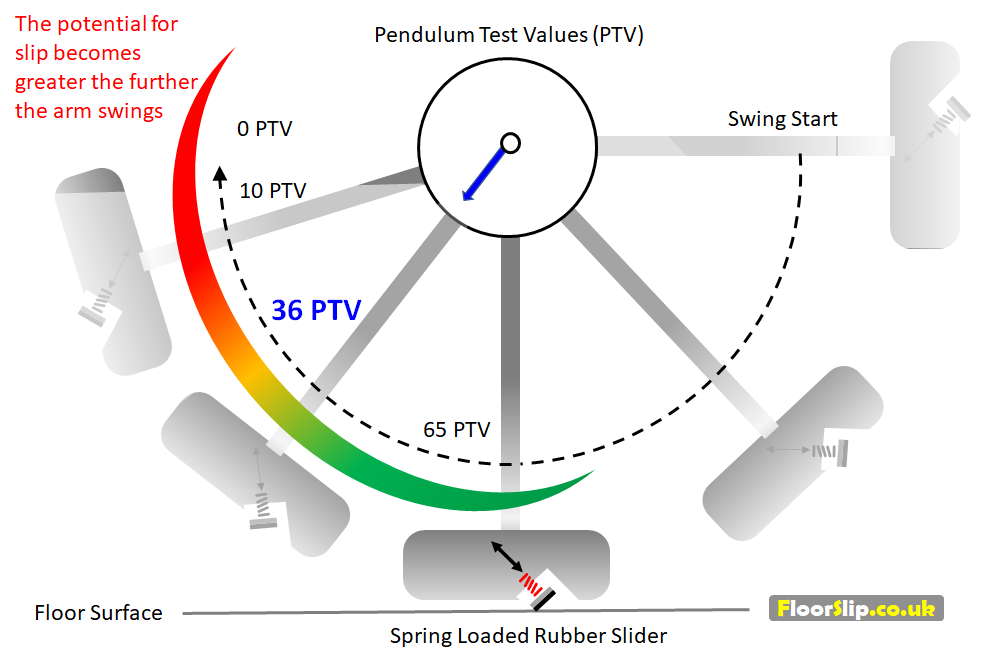

The Pendulum Test Equipment uses a Rubber Slider to replicate the 'Dynamic' (moving) action of a heel sliding across the surface of the floor. In a test swing, the further the 'spring loaded' rubber slider can pass along the floor, then the less friction / slip resistance exists and the more likelihood of slip. The On-Site Floor Pendulum Testing or Off-Site Floor Sample Testing can test your floors for you.

The Rubber Slider Travels further when the floor slip resistance is less

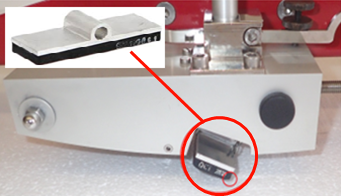

The Rubber Slider shown on the Pendulum Foot of the Pendulum Test Equipment

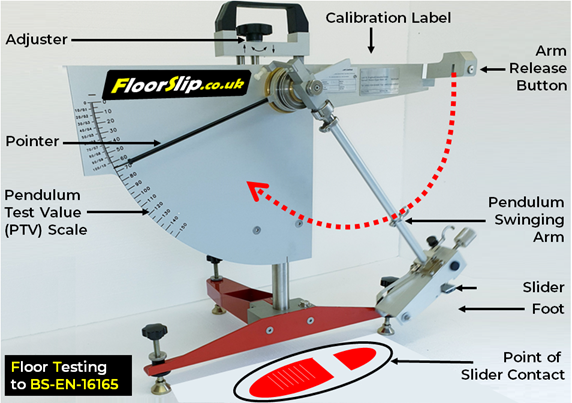

The Pendulum Test Equipment - The Spring Loaded Slider scrapes across the floor at the 'Point of Slider Contact' indicated

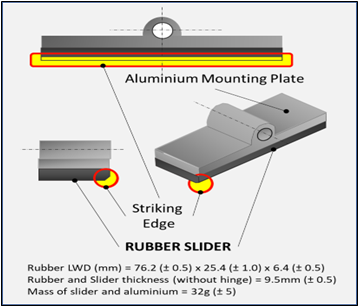

The slider is made from an aluminium backing plate with rubber bonded onto it. The rubber has different hardnesses to represent different circumstances.

The makeup and dimensions of the Rubber Slider

The hardness, known as the IRHD (International Rubber Hardness Degree) is either: -

Slider # 96 - to replicate shod feet and typically smooth soled or lightly profiled shoes and typiacllu sued on smooth floor surfaces

Slider # 55 and #57* - to replicate bare feet or heavily profiled shoes and boots such as the soles found on working boots or for use on profiled surfaces.

* Slider #55 has been in circulation for over 20 years. In 2011, Slider #57 was also supposed to be introduced under Airfield and Road Testing Standard BS-EN-13036-4 and again called up in 2022 under Floor Testing Standard EN-16165. However, Slider #57 is still not available to purchase and so Slider#55 continues to be the slider used instea dof Slider #57 - see Floor Testing Standards for further detail

By its very nature of being manufactured from rubber, the slider wears at its 'striking edge' (see image above) as it scrapes across the floor to replicate the action of the heel. There are British and European Standards governing the limitations of use, unfortunately, the various Floor Testing Standards do not offer a consolidated approach (See the table further down).

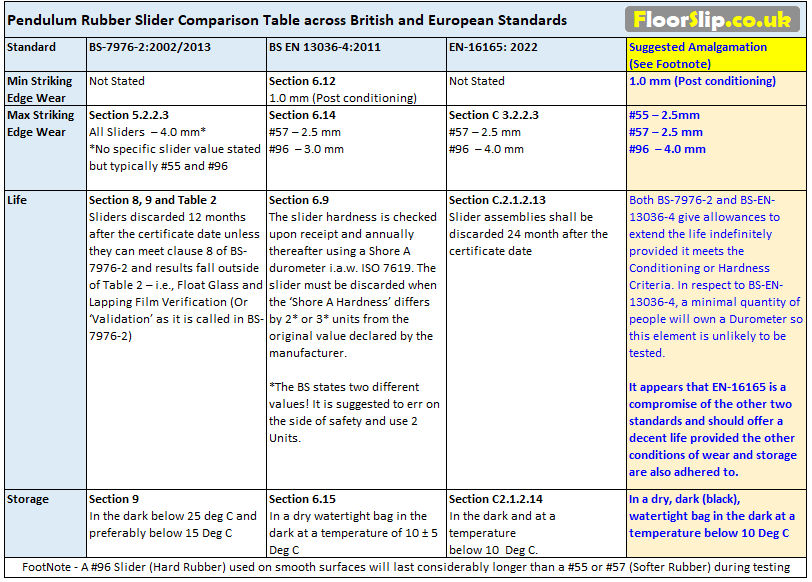

It is therefore suggested the following criteria should meet with the largest majority of the standards...

Rubber slider wear limits: -

(Outside of the ranges below, there is a likelihood of inaccuracy with readings).

Slider #96

Minimum 1.0mm to maximum 4.0mm

Slider #55 / #57

Minimum 1.0mm to maximum 2.5 mm

Storage:

In a dry, dark (black), watertight bag in the dark at a temperature below 10 Deg Centigrade.

Expiry:

Slider assemblies shall be discarded 24 month after the certificate date

Table of Comparisons of Rubber Slider limitations