FAQ’s on Floor Slip Testing

FAQ Topics on Floor Testing, Safety & Slip Injury

HERE1

6. Floor Safety

9. Buying and Specifying Floors

10. UK HSE / HSL

11. UKSRG

(OPEN POP UP WINDOW For Acronyms & Glossary)

Section 1 - FLOOR TESTING / PENDULUM TESTING

(OPEN POP UP WINDOW For Acronyms & Glossary)

Main Navigation Links

1.1 - What is floor pendulum testing?

The use of specialist Floor Testing Equipment to determine the ability of a floor surface to resist slips. See our sections on What is Floor Testing? And Why Floor Test?

1.2 - How do I get a PTV (pendulum test value) for a floor surface?

The PTV or Pendulum Test Value is found by having On-Site Floor Pendulum Testing or Off-Site Floor Sample Testing conducted using the Floor Pendulum Test Equipment

1.3 - Is PTV and SRV the same thing?

YES. PTV means Pendulum Test Value. SRV means Slip Resistance value. They are interchangeable terms

1.4 - What does PTV mean?

PTV means Pendulum Test Value and is a value of ‘coefficient of friction’ produced by Pendulum Testing. On a horizontal surface*: -

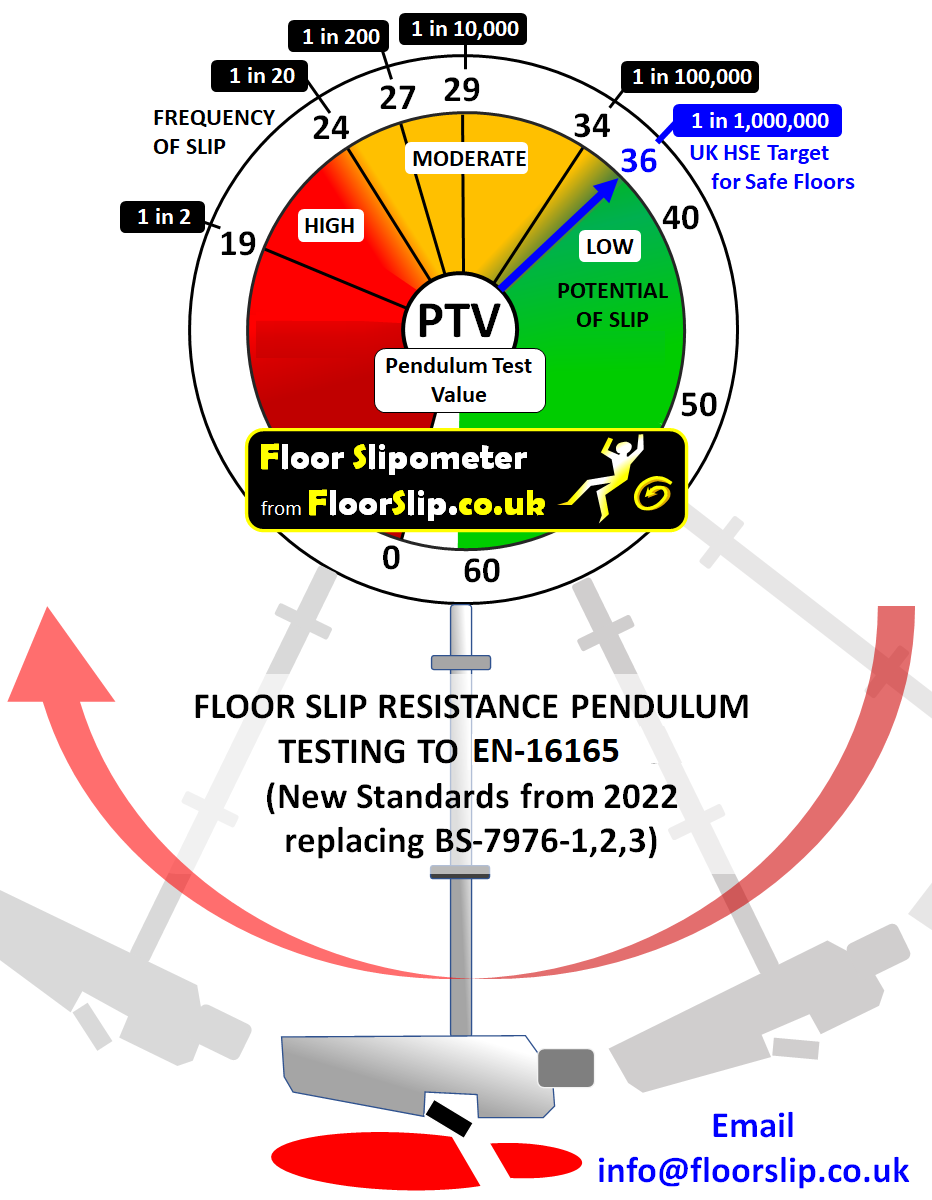

- Values above 35 PTV are classified as a LOW Slip Potential

- Values from 25 to 35 PTV inclusive are classified as a MODERATE Slip Potential

- Values below 25 PTV are classified as a HIGH Slip Potential.

Read About the Slip Probability and Slip Potential

*On a sloping floor, the values must be adjusted - See Floor Slopes

1.5 - Who can test my flooring for slip resistance?

A firm, such as FloorSlip skilled in the use of the Pendulum Test Equipment complying to British / European Standards on Floor Testing and also ideally UKSRG Guidelines performing the tests with UK Manufactured Calibrated Floor Testing Equipment, which can be purchased through FloorSlip

1.6 - Which slip test should I use?

The preferred method of choice, promoted by the UK Health and Safety Executive recognised by industry, expected by Lawyers in Slip Injury Claims and the UK Courts, is the Pendulum Test. Note that if other methods are chosen that it is highly unlikely that tests conducted will stand up to the scrutiny of a Court and opposing Expert Witnesses in Slip Accidents

1.7 - Can floor pendulum test results be used in a slip injury claim?

DEFINITELY, provided that: - The equipment used to test is of a quality make and proven to be calibrated and Verification Results are acceptable. The British / European Standards on Floor Testing and the UKSRG Guidelines for Testing have been accurately and thoroughly followed.

1.8 - Where can I buy the floor pendulum test equipment? What do I need? How much will it cost?

FloorSlip sell new UK Manufactured Floor Pendulum Test Equipment at competitive prices. You will need a Floor Pendulum and Equipment Slider Verification Equipment; a Floor Surface Roughness Tester; a copy of the latest British Floor Testing Standard; a copy of UKSRG Guidelines; Training in the use of Equipment and the Documentation. Aim at a budget of £10,000. Alternatively Contact FloorSlip and we will conduct the testing for you at a fraction of that price

1.9 - Should I buy a cheap online import of a pendulum test equipment?

WE WOULD NOT ADVISE IT. There is no guarantee that the results will be accurate; spares are almost impossible to obtain and UK Test houses are unlikely to calibrate the equipment annually (which is the requirement).

1.10 - Can I have my pendulum calibrated outside the UK?

YES. But always find a reputable company that conducts tests in accordance with EN-16165 (For UK and Europe)

1.11 - I am struggling to use my pendulum test equipment. Who can I call for help?

Contact FloorSlip. We will always help regardless of your question. All our operators are very skilled in Floor Testing; we can also offer On-site Pendulum Test Equipment Training Courses at your establishment

1.12 - What standards are used for floor pendulum testing in the UK?

Prior to 2022, (British Standard) BS-7976-2 and from 2022 use (European Standard) EN-16165 for pedestrian surfaces, though both may be required in use until further notice; See Floor Testing Standards. It is always strongly suggested to use the UKSRG Guidelines (Issue 5 for BS-7976-2 / Issue 6 for EN-16165) along with the British / European standards, which fill in the gaps left by the British and European standards.

1.13 - What standards are used for road and airfield pendulum testing?

BS-13036-4 is the Standard used for Road and Airfield surfaces Testing

1.14 - Do I need UKAS accredited test house to conduct floor pendulum testing?

NO. UKAS accreditation simply states the body of UKAS has done an inspection of the premises, equipment and procedures and finds them acceptable, unfortunately this makes the testing more expensive than FloorSlip will offer it for and FloorSlip are Dedicated Experts in Floor Slip Testing See Prices of Floor Testing

1.15 - Which floor slip test should I use?

It is always suggested to use the Floor Pendulum Test in the UK as it is the only test that gives a true Dynamic Coefficient of Friction, which imitates the action of a heel sliding across a floor whilst walking. The UK Courts also fully recognises the Floor Pendulum Testing in courts of law in Slip Injury Claims, Which FloorSlip Specialise In.

1.16 - How long can I rely upon a floor slip test certificate?

With average footfall, 12 months from date of test. On high footfall, e.g., train station, airport, end of an escalator etc. it is suggested to do twice annually. Consider also Floor Surface Monitoring in between tests, which will give you an indication where a floor slip resistance is reducing prematurely.

1.17 - When should I do floor testing and why?

Every annual Risk Assessment should include floor safety assessments / On-site Floor Pendulum Testing; this will help demonstrate if the floor is safe against Slip Injury Claims and meets the Legal Requirements for Safe Floors. If the building is new to you and there is no evidence of floor testing, then get it carried out as soon as reasonably possible, especially in areas likely to become wet or suffer from spills or environmental ingress (Rain, snow, fog etc). Contact FloorSlip with your Floor Testing Requirements

1.18 - How many pendulum floor tests should I conduct on my premises and which should I test?

Every floor surface that is not rough concrete, tarmac, nor carpeted should be considered. To determine the quantity, assess what floor surfaces you have which are the same as this will reduce quantity. E.g., a shopping centre is often laid to the same floor surface. Definitely include those that may become wet from environmental ingress (rain/snow etc) and contaminants relevant to each locale to determine if the floor is likely to provide a low slip potential safe against Floor Slip Accident Claims and to meet Legal UK Requirements for Safe Floors.

1.19 - What is ‘Pass’ on a floor pendulum test?

The UK HSE do not dictate pass / fail criteria. The UK HSE recommends that if a floor is likely to become wet or contaminated that a recommended / expected minimum value of 36PTV should be aimed at (increasing by about 1.75 PTV for each 1 degree of slope). If a floor cannot achieve the 36PTV value, then provided the floor will not become wet / contaminated, or does so only occasionally and an immediate rapid clean and dry is carried out or cordoning off occurs until the floor can be cleaned, and this action can be repeated quickly every time, then Applying ALARP Principals (As Low as Reasonably Practicable) can be deemed as suitable.

1.20 - My floor has failed the pendulum test. What can I do?

The term ‘fail’ is not one that is specifically applied, if you mean, the floor has not achieved 36PTV when wet / contaminated, then consider what the floor will be used for and the amount of traffic. If a floor will be predominantly wet and high traffic, then consider replacement of sections that fail or maybe use non-slip coatings. If the floor will be dry the largest percentage of time with minimal spills that through policy and repeatable actions can be effectively and swiftly cleaned then a lower value than 36PTV might be deemed as acceptable – read the section on ALARP. Contact FloorSlip and we can talk you through the scenarios.

1.21 - What PTV value should I am at as a floor specifier?

If the floor will definitely become wet or contaminated on a regular basis, then a minimum of 36PTV on a horizontal slope should be specified, adding 1.75 PTV for every 1 Degree of Slope. Ideally start at higher than 36PTV to allow for wear; e.g., 40 to 45 PTV. If a floor will ‘occasionally’ be wet from spills (e.g., a shopper at a supermarket drops a bag of flour (dry contaminant) or a bottle of milk (wet contaminant) then again choose 36-40 PTV if there is a likelihood that the policies of the customer will not be robust to quickly and effective clean up spills. Where a floor will remain definitely dry on a constant basis, then floors with lesser value than 36 PTV when tested wet, MIGHT suffice provided any spills that do occur are very quickly and effectively dealt with, which is not easy for a specifier to know unfortunately. See the Section on Specifying Floors

1.22 - Can I test my own floors?

Certainly. Though we always strongly advise you perform Training in Floor Pendulum Testing Equipment. On the face of it, the equipment and the methods may appear simple but we can tell you, after 12 years in this business conducting testing for business and in Slip Injury Claims, there is always something new to learn and the Floor Test Standards are complex to follow

1.23 - What is a Coefficient of Friction (CoF) in a pendulum test?

Consider that there are two aspects – Dynamic (moving) friction or Static (Fixed Friction).

DYNAMIC COF is how the Floor Pendulum Test works and is the force of friction between two objects whilst the Rubber Slider of The Pendulum Test Equipment Arm is swinging across a floor surface’, e.g., in walking, a person’s shoe heel tends to slide along the floor surface in its movement; the coefficient of dynamic friction (µD) is the measurement of that friction.

STATIC COF is a force that resists movement of an object pressed upon it, e.g., a person stood on a floor and the coefficient of static friction (µS) is the minimum force required to get that person to slide from standstill to moving on that surface. The coefficient has no value but ranges between 0 (no friction) and 1 (most friction, where it would take as much force to lift the person as it would to slide the person) and the value of 1 is the maximum provided no substance, e.g., Velcro or glue, is used to hold the object to the surface.

1.24 - What is PTV? How does it relate to COF?

PTV stands for Pendulum Test Value. The scale on the Pendulum Test Equipment shows values from 0 to 110 PTV and is simply the COF (Coefficient of Friction) multiplied by 100. So, for example, a COF of 0.36 would give a Pendulum Test Value of 0.36 x 100 = 36 PTV.

1.25 - Is the MEDIAN (middle) or MEAN (average) PTV result used in a test?

During the Floor Testing Using the Pendulum Test Equipment, the pendulum arm is swung across the surface being tested 3 times for settling the equipment and a further 5 times to ascertain the test result; it is the middle value (median) of the range of 5 readings attained. For example, readings of 16, 19, 18, 17, 16 when reordered would be 16, 16, 17, 18, 19 and the middle number is 17.

1.26 - What is the limitation of life and wear on the pendulum rubber sliders?

Unfortunately, this all depends on which Floor Testing Standard or Road-Testing Standard you consult. See more information on the table on Rubber Sliders

In general, amalgamating the data from the standards, the following is suggested: -

- Rubber slider striking edges wear limits:

- Slider #96 Minimum 1.0 mm to maximum 4.0 mm

- Slider #55 / #57: Minimum 1.0 mm to maximum 2.5 mm

- Expiry: Slider assemblies shall be discarded 24 months after the certificate date

- Storage: In a dry, dark (black), watertight bag in the dark at a temperature below 10 Deg Centigrade (Fridge*).

*Before issue, the manufacturers store the Rubber Sliders in a light, temperature and humidity-controlled environment, which considerably slows down degradation of the rubber. But this status is generally impossible to maintain after they are released from storage.

1.27 - Why do rubber sliders cost so much?

They are not mass produced. They are hand made in small batches only and there is no guarantee that a batch will achieve the required shore hardness values (#55 or #96 in the UK); as a result, batches are sometimes rejected making the costs higher. See Prices of Rubber Sliders

1.28 - What tolerance is allowable on a pendulum test value (PTV)?

There is no specific tolerance. A repeatability of test of +/-1 PTV using slider #96 is considered the norm when the Pendulum Test Equipment is set up accurately, verified for use and calibrated correctly and annually. Note 1 PTV at a reading of 36PTV can vary the probability of slip from 1 in 1 million down to 1 in 100,000 as Slip Probability (frequency) is an exponential value.

1.29 - BS-EN-13036-4 section 13 mentions Standard Deviation is this the same as tolerance?

NO, it is not the same as tolerance; there is no specific tolerance. Suffice to say, if the Pendulum Test Equipment is set up and verified properly then in use, using slider #96, a repeatability of test of +/-1 PTV should be the norm. It is also important to keep the Pendulum Calibrated correctly (annually) to ensure accurate readings. See more about BS-EN-13036-4 in Road Surface Tests.

1.30 - If I test with a slider #55 (or #57) as well as #96, which is the correct reading to use in my tests?

Always use the LOWEST WET / CONTAMINATED reading regardless of the slider it was tested upon, which gives the truest worst-case ability of slip resistance.

1.31 - I have tested a floor at just below 36 PTV when WET; is this OK?

A floor that is found to have 36 PTV when tested on a wet horizontal floor surface (No Floor Slope) is said by the UK HSE to able to deliver a floor surface that has an acceptably low risk of slipping for pedestrians when wet (wet floors account for 95% of slips) with a ‘Low Potential for Slip’. Below 36 PTV, the potential for slip moves to ‘Moderate’ and the probability / frequency of preventing slip decreases exponentially 10x from 1 in 1,000,000 at 36PTV to 1 in 1,000,000. However, other ALARP Factors and not just the PTV value are as important for floor safety: for example, such as how a floor has been managed in respect to Risk Assessments, Slips and Falls recording and investigation, Cleaning and Spill policy and methods, Historic Testing and Floor Surface Roughness Monitoring etc. Also, the amount of footfall is relevant in assessing probability. In the case of a Slip Injury Claim, then, some courts rule hard and fast on the 36PTV, others recognise ALARP arguments.

1.32 - What temperature adjustments should be made to the TARGET PTV for a #55 or #57 slider?

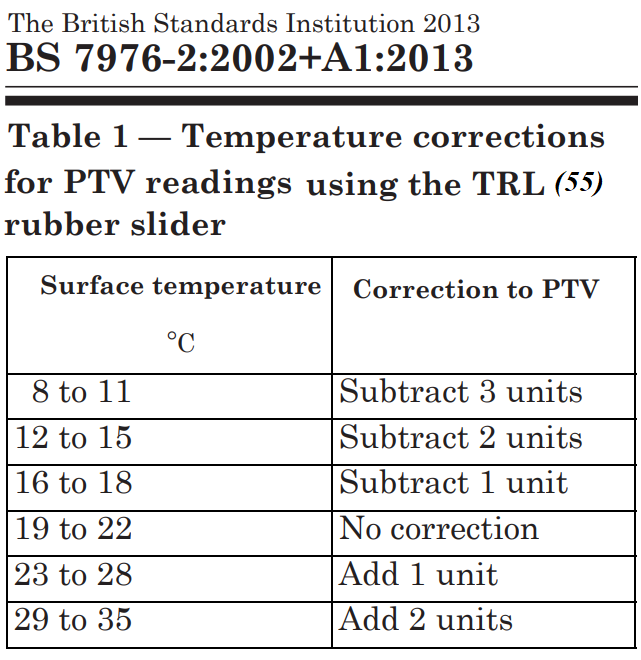

For BS7976-2 (2002 + A1:2013)

Use the Table at BS-7976-2 Section 6.3.2 – as shown here:

For BS-EN-13034-6

Section 9.1.3 - The test can only carried if ground / slider are in the range 5°C to 40°C

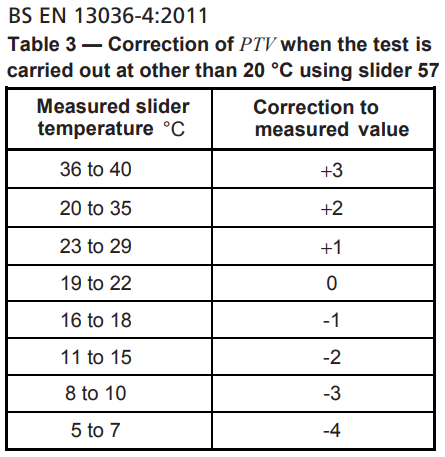

Use the Table at BS-EN-13036-4 Section 12.5 – as shown here:

For EN-16165 (2022)

In simple terms, once the median (middle value) test result has been found and the slider temperature known then these 2 values can be plugged into a formula C1 of EN-16165 section C.5.3. This states that a PTV correction will be made for the rubber slider 57 for ‘PTV adjustments corrected to 20° C. The formula states the Corrected Value = Median PTV Result divided by (1 – (0.0059 x (slider temperature recorded – 20)).

For Example:

- 16 Median PTV at 13°C = 16 / (1 – (0.0059 x (13-20))

- which equals 16 / 1- - 0.0413

- which equals 16 / 1.0413 = 15.365 (15.4 on the table and rounded to 15 PTV).

- Alternatively, use the look up table created in Floor Testing Standards

1.33 - What temperature adjustments should be made to the TARGET PTV #96 slider?

No adjustments required with the harder rubber (#96 is harder than #55 or #57)

1.34 - What is a ‘TARGET’ PTV?

The ‘Target PTV’ is that Pendulum Test Value required once the Floor Slope has been taken into account. For example, the normal target is 36PTV for safe floor when tested wet on a horizontal or 0 degree slope. But for every 1 degree of slope a value of 1.75 PTV must be added to the baseline 36PTV. For example, a floor at 4 degrees slope would require 36 PTV + (4 x 1.75) = 36 + 7 PTV or a TARGET of 43 PTV.

1.35 - What do the numbers #55, #57 and #96 refer to on rubber sliders?

The sliders are named according to the hardness of the rubber; generally known as the International Hardness Rubber Degree or IRHD:

- The IRHD of the rubber pad (compound) measured i.a.w. ISO 48 and ISO 7619-2

- The initial resilience of the rubber pad measured via Lüpke Rebound Hammer i.a.w. with ISO 4662

- The 'Shore A Hardness' of the rubber on the aluminium backing plate measured by the Durometer-method in accordance with ISO 7619-1

1.36 - Should I test with a #55 (or #57) or #96 rubber sliders?

- If a floor will be used predominantly by persons principally in bare feet and it will get wet regularly; for example, showers – then use a #55 or #57 slider.

- If a floor will be used by a mix of persons in bare feet and shoes in a wet environment; for example, swimming pool changing rooms, then use a #55 or #57 and a #96 as well ensuring to use the LOWEST value found for all sliders used, which gives the truest worst case ability of the slip resistance.

- If a floor is profiled (ridges, bumps, dips, striations, coarse surface, checker plate etc) use a mix of #55 (or #57 if available) and #96 and use the LOWEST value found for all sliders used; but note, if the #96 jars and judders when the test is conducted, then only use #55 (or #57 if available), which gives the truest worst case ability of the slip resistance.

- If a floor is predominantly used by person in cleated work-boots (which typically have a rubber sole / heel hardness similar to the #55/#57 rubbers) then use mix of #55 (or #57 if available) and #96 and use the LOWEST value found for all sliders used, which gives the truest worst case ability of the slip resistance.

If a floor is smooth and will be used predominantly by persons in everyday shoes (for example, a shopping mall) – use #96

1.37 - EN-16165 and BS-EN-13036-4 list a #57 slider, can I use the #55-slider instead?

YES. At the current time (2023) there is no choice but to use the #55 slider as the #57 slider is not available from manufacturers. The tolerance for #57 sliders allows #55 sliders to be used in many cases (see the Section on Rubber Sliders). Additionally, the UK HSE and UKSRG recognise the #55 slider and have carried out many tests in respect to its performance over many years and characteristics to justify the use of the #55 slider; the UKSRG Issue 6 (Draft) is likely to be published at next issue stating the use of #55.

1.38 - Why under EN-16165 has the max wear allowed on the #55-slider reduced from 4.0 mm under BS-7976-2 to 2.5 mm?

In depth tests with the #55-slider by various leading research bodies have proven that the Pendulum Test Results may be erroenous beyond 2.5mm wear on the #55 / #57 sliders.

1.39 - Where does the Frequency (probability) of Slip data the term 'Potential of Slip’ originate from?

From a body of work conducted by Pye and Harrison on behalf of the UK HSE and HSL. The data is old and the sample set small but has become accepted values across the HSE and legal entities and there should not be a problem when quoting it.

1.40 - My floor has achieved less than 36 PTV, what is the Frequency (Probability) of Slip likely to be?

The image below of the ‘Floor Slipometer’ informs about the various values for the PTV results obtained (Black and Blue labels - e.g., 1 in 10,000). The inner labels of the clockface inform the UK HSE/HSL classification of 'Slip Potential' (High. Moderate, Low)

1.41 - I have tested with #55 (or #57) and #96 sliders, which value should I select as the final value?

The LOWEST value regardless of which slider it is found on, which gives the truest worst-case ability of slip resistance

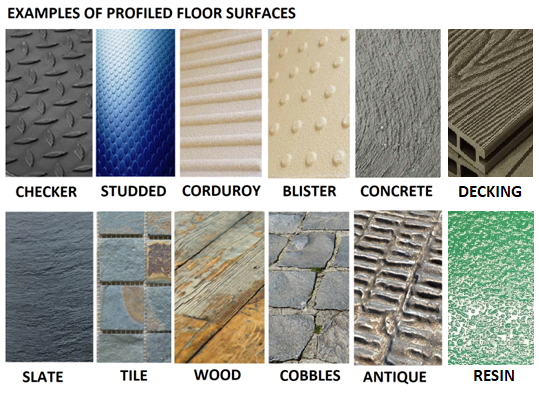

1.42 - What defines a profiled surface?

This is a subjective subject. Loosely speaking, any surface which is not a smooth surface and has raised geometric or non-geometric patterned surface.

1.43 - I have floor test data from two sources, which do I select?

Check the background of the data. Are the companies both reputable? Did they use British or European Standards and UKSRG Guidelines? Have they provided certificates of Calibration for Equipment and Sliders and are they all within date? Is the data like for like? E.g., did they use the same sliders and same equipment types? If all this is the same then the chances are that they will be very similar results. If there are differences, then they might be as a result of testing on different areas of the same floor surface location, which can vary depending upon wear. In all cases, always pick the LOWEST value, which gives the truest worst-case ability of slip resistance.

1.44 - My floor will ALWAYS be DRY so do I need a floor pendulum test?

Probably not, but it is always better to have a known best value starting point (Dry) and actually know what the PTV values both Dry and Wet floors achieve. Dry floors nearly always pass a pendulum test, but consider what circumstances the dry floors will be used in. For example, if it was young children running around in socks on a smooth shiny floor, then the child will slip as easily as if it is a slip by a shoe on wet shiny floor; it is therefore necessary to know that the floor will be safe for the circumstances it will be subjected to.

1.45 - If the floor will only be used WET, do I need to do a DRY Pendulum Tests?

Not Really; but see above answer

1.46 - Can heavily profiled surfaces like manhole covers be tested?

Only in some cases. Note that many such surfaces are not as non-slip as it is initially considered because smooth shoe soles and heels can slide across the tops of any flat profiling; sharp / pointed profiles are better for this. A rusty metal manhole will give better slip resistance readings than a new shiny / galvanised one. The UKSRG Guidelines has a section on Profiled Surfaces, which might prove useful (Contact FloorSlip and we will talk you through the ‘Profile’ scenarios); also see the FAQ on profiles surfaces further above.

1.47 - Is there a read across from PTV to R Ratings (R9, R10, R11, R12 and R13) or ABC Ratings or vice-versa?

NO. The Ramp Test carried out under DIN Standards was used to determine the R-ratings (shod) and ABC -Ratings (barefoot) and as part of the ramp test, a pendulum test could ALSO be conducted, which arrived at a value for a specific floor with specific contaminant and particular shoe / heel combinations. It is only if these exact same conditions could be applied under normal pedestrian activities could this PTV to Rating relationship exist, but as this is unlikely to ever happen then the only true value to determine a floors ability to resist slips is the Off-Site Floor Sample Pendulum Test or On-Site Floor Pendulum Test.

1.48 - What PTV should I have on stairs?

Stairs have one of the highest incidents of deaths in the UK of many hundreds of people so the answer is quite simple, always aim at achieving 36PTV or better when wet tested particularly at the nosings (the leading top edge of the step). In low visibility environments in commercial buildings, make sure the nosings are high contrasting / high visibility to meet UK Laws on Floors. (2023) There is a likelihood in the not-too-distant future, that UK building Regulations will increase the requirements to make stairs safe by (a) having a longer ‘Going’ of the step (the horizonal floor surface) to accommodate foot sizes of today’s population); and (b) expect all stairs to be lit at foot level

1.49 - I have a floor slope; does it affect the PTV?

DEFINITELY. Any slope will reduce the ability to resist slips. Imagine this, you can stand on a flat muddy field without falling, but how easy is it to stand on a sloping muddy hill? Always increase your target PTV by 1.75 PTV for every 1 degree of slope (try to limit slopes for the disabled to 5 degrees) – see our sections on Floor Safety Building Regs and Floor Slopes.

1.50 - How do I measure a floor slope?

Digital inclinometers are available for approx. £20. There are also ‘APPS’ on phones but how accurate they are is unknown.

1.51 - Can I conduct a pendulum test on a floor slope?

YES. Up to 10 degrees.

1.52 - I have a steep slope greater than 10 degrees, can I get it pendulum tested?

YES. We would select a floor of the same type and wear at the site but of a horizontal or shallower slope and tie up the floor surfaces both visually and for Floor Surface Roughness. The results from the shallower slope would be representative of the steeper slope but read-across to the steeper slope; the final TARGET Pendulum Test Value (PTV) adjusted for the slope measured on that floor that could not be tested.

1.53 - Has floor test equipment/slider verification changed under EN-16165?

YES. Consult EN-16165 or See Our Page on STANDARDS > VERIFICATION TABLES

1.54 - How is Slip resistance assessed in bare foot situations such as a bathroom or pool?

Typically, just a #55 (or#57 if available) is used for barefoot testing. However, also consider the users of that floor. If it is likely to be purely bare feet, such as a jacuzzi – then just #55 (or#57). if it is likely to have a mix of bare feet and shod feet, such as when shod staff are in attendance or when customers are changing in a changing room, then use #55 / #57 and #96 (shod). NOTE - Where both sliders are used, #55 (or #57) and #96, it is the LOWEST value from all sliders, which is the one to recognise as the worst state of floor safety

1.55 - BS 7976-2 uses ‘MEAN’ PTV and UKSRG Issue 5 uses ‘MEDIAN’ PTV, which is correct?

MEDIAN or ‘middle value’ of 5 test swings undergone in each direction of test (following 3 settling swings in each direction).

1.56 - Can I Hire pendulum test equipment?

There are only a ‘limited’ amount of companies that will hire out the Pendulum Test Equipment as it is a sensitive piece of equipment and prone to damage if not handled properly. But unless the tester is skilled in its use, then the results are likely to be flawed. We always suggest get Pendulum Testing Conducted by an Expert – Contact FloorSlip for your needs

1.57 - Do I need training to use the pendulum test equipment?

YES. We strongly suggest any new user undertake training with an experienced operator. – Check out our Training of Operatives in the Pendulum Test Equipment performed on your site.

1.58 - I am a floor manufacturer; can I test my floors to be able to declare independent slip resistance values?

YES. There are 2 principal tests performed to EN-16165. The first is a Ramp Test, which is designed to determine the interaction of a floor surface with a SPECIFIC shoe type and SPECIFIC contaminant; unfortunately, this does not give a GENERIC VALUE suitable to sell / market floors. The second and Preferred is the Floor Pendulum Test, which gives a very accurate Pendulum Test Value (PTV). If you want to be able to sell your floors to just about anyone, then a value of at least 36 PTV is needed when the floor is tested WET but note that a floor surface of 40-45 PTV will allow for wear and Floor Slopes. FloorSlip can conduct Off-Site Floor Sample Tests for you

1.59 - Can the 'SlipAlert' be used to replace the pendulum test for on-site slip measurements?

It has limited use. For example, stairs, tight areas like bathrooms, baths and rough floor surfaces cannot be tested with them. The results are not the same and have to be read across to a Pendulum Test Valeu (so it makes sense to do the Pendulum Test in the first place).

Section 2 - FLOOR SLIP INJURY CLAIMS

(OPEN POP UP WINDOW For Acronyms & Glossary)

2.1 – Can I claim for a Slip Injury Accident on a floor surface?

For example

- At or in a Swimming Pool / Changing Rooms / Gym?

- In a Shopping Centre / Shop / Market?

- In Offices / Reception / Workshop?

- In a Hotel / Bathroom / Kitchen?

- On Stairs / Ramps / Corridors etc.?

YES. In the UK, there are Laws on Floors that legislate floors will be safe for the use they will be put to.

2.2 – I have slipped / tripped on a Pavement and injured myself. Can I claim?

YES. In the UK, there are laws on that legislate floor surface will be safe for the use of pedestrians / cyclists. Each council tends to have their own criteria but this is / should be largely based around UK Legislation of Laws on Floors

2.3 – My car has skidded on the road, I crashed and injured myself. Can I claim?

Possibly. If it can be proven the road was the source of the issue and was not able to provide an effective non-slip surface that met local council regulations. Tests performed under BS-EN-13036-4 covers slips on Roads and Airfields

2.4 – I have slipped in my car on the road, crashed and injured myself. Can the slip resistance of the road be tested?

YES. The Pendulum Test performed under BS-EN-13036-4 covers slips on Roads and Airfields

2.5 – I have slipped and injured myself, what can I do?

Please consult our Page ‘I Have Slipped – Help me’

2.6 – I have slipped and injured myself, what are my rights?

In the UK, there is Legislation / Laws On Floors that floors will be safe for use. We would suggest contacting a Slip Injury Lawyer and ask their opinions.

2.7 – I have slipped and injured myself, how much can I claim?

We cannot help you but we deal with a lot of Slip Injury Accident Lawyers who would not be in business if they couldn’t arrive at a suitable figure to cover injuries, time off work, medical bills and long term compensation if it is necessary. We suggest contacting a Slip Injury Lawyer and ask their opinion. Read some of the articles on other slip injury accident claims

2.8 – What are the rules on floor safety in respect to slip injury accident claims?

A floor surface and fixtures should be fit for the purpose it was designed for. This could include Floor Slip Resistance Values (determined by Floor Slip Resistance Testing), Floor Slopes, Building Regulations, Handrails, Stair Design, Lighting and so on.

2.9 – I have slipped and injured myself who can test my floor for slip resistance?

A reputable company like FloorSlip, who specialise as Expert Witnesses in Floor Testing conducting Floor Tests to British / European Standards and preparing UK Court Reports on behalf of Slip Injury Lawyers

2.10 – I have slipped is there a test to prove if a floor is slippery?

YES. The Floor Pendulum Test conducted to British / European Standards recognised by the UK Health and Safety Executive (HSE) as suitable for UK Courts in Slip Injury Claims

2.11 – I have slipped and injured myself on holiday abroad. Can I claim?

Possibly, subject to discussions with a Slip Injury Lawyer. If you have suitable evidence such as decent quality photos of the floor surface and medical reports, expenses and receipts etc. then it is sometimes possible to carry out a ‘Desktop Analysis’ if the site cannot be physically visited due to the costs involved. FloorSlip have carried out such procedures before. ‘See more at I have Slipped – Help Me!’

2.12 – I have slipped and injured myself on a cruise ship. Can I claim?

Possibly, subject to discussions with a Slip Injury Lawyer. If you have suitable evidence such as decent quality photos of the floor surface and medical expenses receipts and reports etc. then it is possible to carry out a ‘Desktop Analysis’ if the site cannot be visited. But if the ship docks in a UK harbour, then it may be possible to conduct an On-Site Floor Pendulum Test. ‘See more at I have Slipped – Help Me!’

2.13 – Are there people who specialise in Slip Injury Claims?

Yes. The UK has many Slip Injury Lawyers; see the List of the Slip Accident Lawyers we deal with regularly

Section 3 - FLOOR RAMP TESTING / R-RATINGS and ABC RATINGS

(OPEN POP UP WINDOW For Acronyms & Glossary)

3.1 - What is the purpose of floor ramp testing?

The Ramp Test is to ascertain the slip resistance between a particular shoes type on a particular floor surface using a particular contaminant. I.e., they are specific for task and NOT designed to be used for generic flooring specification.

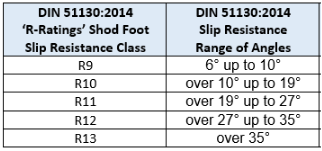

3.2 - What is an R Rating?

It is a classification during DIN 51130 ramp testing determined by the angle of a sloping floor when a slip occurs on an oil-soaked surface walked upon by a human shod foot tester. The angle of the slip denotes the R-Ratings; ranging from R9 (shallow slope) to R13 (steepest slope); there is no value below R9.

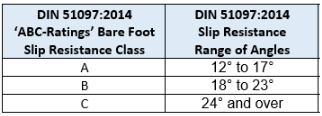

3.3 - What is an ABC Rating?

It is a classification during DIN 51097 ramp testing determined by the angle of a sloping floor when a slip occurs on a surface wetted with a soapy solution walked upon by a human shod foot tester. The angle of the slip denotes the ABC-Ratings; ranging from A (shallow slope) to C (steepest slope).

3.4 - Is there a read-across from ramp test R-Ratings / ABC Ratings to a pendulum test value?

NO. For years, the UK HSE showed a ‘read-across to PTV from R-Ratings’. This has been removed from the HSE website (presumably as it was incorrect). The original data was not for generic floors but was instead aimed at testing a footwear standard and the values arrived at determined by the footwear sole / heel profile; test approach angle; contaminant and viscosity; the floor surface characteristics; the interlock of shoes and floor and the persons’ gait.

3.5 - What is cost of floor ramp testing?

Ramp Tests are significantly more expensive than a Pendulum Test Prices and the Ramp Test can only test specific scenarios and is not able to deliver generic results. If you require further information, please Contact FloorSlip

3.6 - Can I just select an R Rating (R9, R10, R11, R12 or R13) or ABC Rating when selecting floors?

NO. R Ratings / ABC Ratings are arrived at following the testing of specific floors with specific footwear (or bare feet) using specific contaminants. They were never meant for generic specification of flooring. If you are a specifier of floors, then ALWAYS get a Floor Sample Pendulum Tested or look for a spec sheet that CATEGORICALLY SAYS – WET SLIP RESISTANCE (NOT DRY) PERFORMED TO BS-7976-2 OR EN-16165 AND ACHIEVED A MINIMUM OF 36 PTV ON A HORIZONTAL SLOPE.

Noting:

- That, generally, Dry floors do not cause slips, wet floors cause 95% of slips;

- That any Floor Slope will require an additional 1.75 PTV per degree of slope.

3.7 - Does EN-16165 Annex A (Bare Foot) and B (Shod foot) supersede DIN 51097 (Bare Foot) and DIN 51130 (Shod foot)?

The forward of EN-16165 does not state it supersedes the DIN standards. It can therefore only be surmised that both EN-16165 Annex A and B and DIN 51097 / 51130 will co-exist until it is known otherwise.

3.8 - Is there a read across between EN-16165 Annex A and B Ramp Tests and DIN 51097 / 51130 ramp tests?

- Under DIN 51097 (Barefoot) – when a ramp test is carried out, the angular value test results is equated to values known as ABC Ratings.

- Under DIN 51130 (Shod Foot) Ramp Tests, the angular value arrived at is equated to values known as R-Ratings. (R9, R10, R11, R12, R13).

- But under the latest EN-16165 at Annex A (Barefoot) and Annex B (Shod foot) Ramp Tests, only a single angular value is given as the final result with NO translation or read-across evident to ABC Ratings or R-Ratings. (It is unclear how the single angular value will be used in the market place).

3.9 - Does an R-Rating Value (R9, R10, R11, R12, R13) relate/correlate to an ABC rating?

NO, there is no read across. The values are arrived at Shod Foot (R Ratings) and Barefoot (ABC Ratings) using the same equipment but with multiple different parameters

3.10 - Can R Rating values (R9, R10, R11, R12, R13) / ABC Rating values be converted to PTV?

NO. You cannot convert an R-Rating to an ABC Rating. Also see the section on Read-across from R-Ratings to PTV

3.11 - Can Slip Alert values be converted to PTV?

The website of the company that produce Slip Alert say there is a correlation; FloorSlip cannot verify how accurate the data is nor if it is from a qualitative source. The HSE conducted a study comparing the 2 methods in 2006, there are a number of charts in the HSE study that might or might not relate to the data on the Slip Alert website

3.12 - Should floor coverings be specified from R ratings (ramp testing value)?

NO. The DIN standard 51130:2014 Ramp Test used to determine R-ratings for a shod foot arrives at the R value (R9, R10, R11, R12 or R13) by testing a specific floor with specific finish using a specified contaminant and particular heel/sole combinations. It is only if these EXACT same conditions could be applied under normal pedestrian activities could an R Rating be specified. If you must specify floors then search for one marked something like ‘TESTED UNDER BS-7976 OR EN-16165 AND ACHIEVING 36 PTV WHEN WET TESTED. Alternatively, search for the highest R-Rated tile you can find (R12 to R13) and send them to FloorSlip for inependent / impartial Floor Pendulum Sample Testing. A few pounds spent here will save thousands of pounds spent later in trying to make floors non-slippery or paying out in slip injury claims

3.13 - Should floor coverings be specified from ABC ratings (ramp testing value)?

NO. The DIN standard 51097:2014 Ramp Test used to determine ABC-ratings for bare foot environments does so by testing SPECIFIC floors and contaminants under barefoot conditions. It is only if these EXACT same conditions could be applied under normal pedestrian activities could an ABC Rating be specified. If you must specify floors then search for one marked something like ‘TESTED UNDER EN-16165 or BS-7976 ACHIEVING 36 PTV WHEN WET TESTED. Alternatively, search for the highest ABC-Rated tile you can find (‘C’) and send one to FloorSlip for inependent / impartial Floor Sample Testing

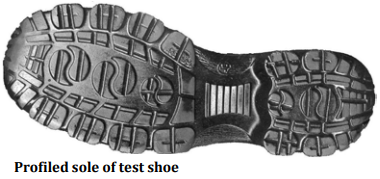

3.14 - What shoes are used in the ramp slip testing under EN-16165?

The sole / heel is rubber of Shore A hardness 73 ± 5 to EN ISO868. The profile is supplied from the supplier-list for testing-materials, Deutsche gesetzliche Unfallversicherung, Fachbereich Handel und Logistik,

Also - see our section on Floor-Testing Standards

Section 4 - FLOOR TESTING STANDARDS

(OPEN POP UP WINDOW For Acronyms & Glossary)

4.1 - I have pendulum tested to BS-7976-2 but EN-16165 is the new standard. Does that mean my floor is no longer satisfactory?

Your floor testing to BS-7976-2 is still acceptable; See Floor Testing Standards. However, consider when it was last tested Ideally, floor testing should be conducted annually as slip resistance generally declines as floors wear over time; even more frequently on high traffic floors. FloorSlip Can Test Your Floors to the latest standards for you

4.2 - What differences are there between superseded BS-7676-2 (2013) and current EN-16165 (2022)?

In summary only (see the Section on Floor Testing Standards for detail) EN-16165 is split up into 4 ‘Annexes’:

- Annex A and B cover Ramp Testing arriving at a single angle of slope as opposed to the ABC-Ratings under DIN 51097 Barefoot Testing and R-Ratings R9 to R13 under DIN 51130 Shod Foot Test.

- Annex C is intended to replace BS-7976-2 Floor Pendulum Testing

- Annex D introduces Tribometer Testing (not often performed in the UK or recognised in UK Courts of Law)

4.3 - What is the cost of EN-16165 and UKSRG Guidelines?

The British Standard EN-16165 introduced 31 Dec 2021 with errata updates in 2022 varies from £140 to £270 (Shop around). The UKSRG Guidelines are more affordable (see their website) and very useful). Issue 6 (due Mid 2023) is relevant to EN-16165; issue 5 (2016) is relevant to BS-7976-2.

4.4 - EN-16165 states to test the rubber slider temperature, how can I do this?

Use an infrared thermometer that can be pointed at the rubber slider.

4.5 - EN-16165 informs me to wait for the rubber slider temperature to settle for 30 minutes before testing. This is not practical for me as I am testing many surfaces. What can I do?

As soon as you arrive on site, take out the slider and by the time you have setup the equipment, verified the Pendulum, taken and recorded slope angles, measured slider and floor temperatures and spoken to the client and relevant parties etc. 30 minutes will probably have elapsed.

4.6 - What build standard is used to manufacture floor pendulum test equipment?

EN-16165 (2022 onwards). Formerly BS-7976. If you wish to buy Floor Test Equipment, then contact FloorSlip; we sell new UK made and designed Floor Pendulum Test Equipment at competitive prices (These are not cheap imported on-line copies either!)

4.7 - Is there a standard for slip resistance of bathmats?

YES - BS 8445:2012 – ‘Bath and shower mats – Testing – Assessment of slip resistance properties’ conducted using the Ramp Test Method. Refer to the section on All Relevant Floor Surfaces Test Standards

4.8 - Is there a standard for slip resistance of bath tubs in the UK?

UK - TBA. The USA have been attempting to define a standard but have run into many issues as it is highly difficult to get manufacturers to agree a standards as each produces different floor profiles and uses different materials. There is also the issue that legacy fitted products may cause a rise in Slip Injury Claims if the standrads were to be set in stone.

4.9 - What standards or documents might guide me in selecting floors?

We can offer 3 suggestions:

- You might like to try our webpage – Buying and Selecting Floors.

- Check out some of the standards listed on our page ‘All Relevant Standards’

- Consult the CIRIA* C652 Publication - Safer Surfaces to Walk On – Reducing the risk of slipping. The guide informs how slips and trips can be decreased and aimed at designers, flooring specifiers, architects & managers.

4.10 - Does floor testing standard EN 16165 (2022) at Annex C replace BS-7976-2 (2013)?

YES. For the large majority of the tests (at Annex C for Floor Slip Pendulum Testing) though there are issues over the Rubber Slider, which may necessitate using the predecessor Standard BS-7976-2 in some circumstances – See Floor Test Standards for further information

4.11 - EN-16165 is due for release in 2022. Will it replace BS-13036-4:2011?

NO. EN-16165 is for Pedestrian footfalls. BS-EN-13036-4 is for Roads and Airfield Surfaces.

4.12 - Will EN-16165 be a ‘complete floor testing standard’? I.e., one not requiring the need refer to the standard as well as the UKSRG Guidelines?

In the ideal world – YES. But this not an ideal world and anomalies in EN-16165 make the UKSRG guidelines even more necessary

4.13 - I have had a floor tested to BS-7976-2 but EN-16165 is now the floor test of choice. Do I need to repeat the test if it was done in a different standard?

NO. But at the next Scheduled Pendulum Floor Test, ensure the latest standard is followed

4.14 - What major differences are there between BS-7676-2 and EN-16165?

There are quite a few. See the web page ‘Floor Testing Standards’ for a detailed breakdown

Section 5 - FLOOR SURFACE ROUGHNESS TESTING

(OPEN POP UP WINDOW For Acronyms & Glossary)

5.1 - What is surface roughness Rz floor testing?

The Surface Roughness Test Equipment determines an Rz value (microns) which is a measure of roughness of a floor and in crude terms the rougher the surface, the less slip is likely. WARNING, DO NOT JUST USE THE RZ VALUE WITHOUT ALSO DOING A ON SITE PENDULUM FLOOR TEST; our experience has shown the Rz parameter to be a less reliable indicator of slip risk.

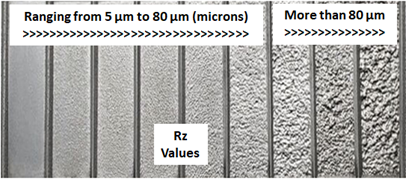

5.2 - What does Rz mean in surface roughness testing?

Rz, measured in µm or microns, is one of 5 terms used in Surface Roughness measuring where ‘R’ is the Roughness and ‘z’ is the maths formula applied to give a value. Rz = where the Surface Roughness Test Equipment drags a very small diamond pointer (the ‘Stylus’) across the floor surface and records the undulations (peaks and troughs) of the surface at microscopic level and averages out the findings to give the Rz Value. The other values are Ra, Rp, Rv, Rmax are not generally used in Floor Testing but instead in engineering applications so not discussed here further.

5.3 - Are there limitations to the surfaces that the Surtronic Duo surface roughness test equipment can be used upon?

YES. The equipment uses a very fine diamond stylus that moves just a few millimetres on the ground to determine surface roughness. The equipment is not suitable for rough ground, profile surfaces where the profiles are close together or soft surfaces like timber decking where the gaps in the grain of the wood can catch the stylus or floor surfaces where the unevenness of teh ground prevents the tester from sitting flat and securely..

5.4 - Should the Surtronic Duo surface roughness test equipment be used in the Wet or the Dry?

The test is only conducted on DRY floors due to the possibility of damaging the electronics from water ingress; the results taken however do not change in the wet or the dry.

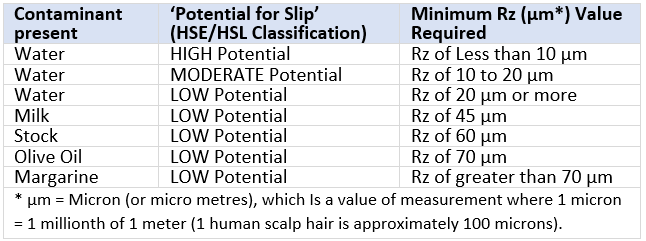

5.5 - The Surface Roughness has to be increased for different viscosities of contaminants; what are these values?

The test results taken are used to determine the effectivity on Wet or Contaminated Surfaces. As the table below shows and higher levels of roughness are required to maintain slip resistance with a more viscous (thicker/ glutenous) contaminant. This data is available in HSE publication GEIS2 informs. HSE publication RR534 gives this data

5.6 – Are there online tools to assist in assessing the slip potential of pedestrian surfaces?

YES. The HSE provide a SAT tool (Slips Assessment Tool)

See further detail at FAQ 9.10

SAT Links on the UK HSE Site

https://www.hse.gov.uk/slips/sat/default.htm

https://www.hse.gov.uk/slips/sat/faqgeneral.htm

https://www.hse.gov.uk/slips/sat/index.htm

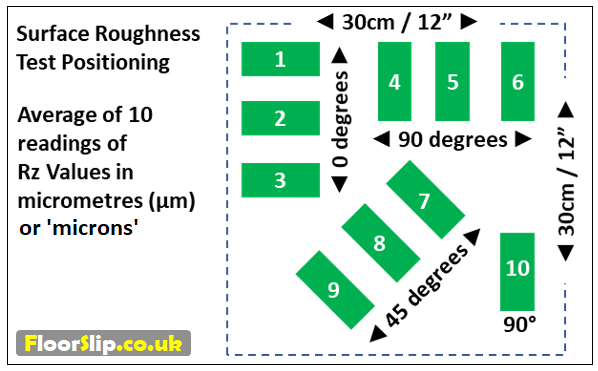

5.7 - Some Testing standards / guidelines say to take 10 surface roughness readings across 3 directions. How do you split 10 evenly by 3?

Taylor Hobson (manufacturer of the test equipment) recommends to take, in an area of 30 x 30 cm, the quantity of 3 at 0 degrees, 3 at 45 degrees and 4 at 90 degrees. None of the positions should overlap.

5.8 - Should the level of a slope also be taken into account with surface roughness test values?

The equipment must be stable when taking the test so ideally a horizontal ground is preferred or there is a possibility that the readings will not be accurate if used on a slope.

5.9 - How much does a surface roughness tester cost?

New – From £2,000 plus VAT

Used – From £500 – (Get the seller to send a video of it working and calibrating correctly before you buy one!)

Note - Although we sell the Pendulum Test Equipment, we do not sell the roughness tester but we can Floor Surface Roughness Test for you - See Checking / Monitoring Floor Wear.

5.10 - Can I hire a surface roughness meter?

We do not have experience of companies hiring them. Maybe consider a second hand one.

Section 6 - FLOOR SAFETY

(OPEN POP UP WINDOW For Acronyms & Glossary)

6.1 - I would like to use safety floors for improved slip resistance but I have heard that they are difficult to clean. is this correct?

Specialist cleaning equipment can be purchased to work with safety floors

6.2 - How can I choose the right tile/flooring for me? What should I look for?

May we direct you to the page 20 Tips on Buying Specifying Floors

Keep in mind that a smooth shiny floor is often (but not always) a slippery floor. The less shine, the better. Also, a floor with a profile like raised buttons or a grid etched into it can, to some degree, assist in slip resistance. A floor with a surface similar to emery cloth or sandpaper and matt in appearance is likely to be OK. IN ALL CASES:

(a) It is NOT recommended to select an R Rated (R9, R10, R11, R12, R13) or ABC Rated surface; these values an be misleading.

(b) Always have any Floor Samples Pendulum Tested Off-Site before laying, for the sake of about a few hundred quid, it might save tens or hundreds of thousands of pounds of pain!! See the Floor Testing Prices

6.3 - I have been told an entrance mat will help to keep my floor clean and safe. What is a correctly specified entrance mat?

A mat that is large enough for wet shoes soles / heels to be THOROUGHLY wiped away before exiting onto a dry floor surface is a good one to aim at. Ideally it will not be a solid mat but one that allows water to drain through it (like a coir mat) into a drained well underneath the mat. The mat should NOT have gaps at the threshold to an outside environment; many Slip Injury Claims occur as a result!

6.4 - Should I need to specify a profiled tile for exterior areas?

Many profiled surfaces are not as efficient at preventing slips as one might imagine. Always have any Samples Floor Pendulum Tested before specifying floors

6.5 - Can the slip resistance of a shiny floor surface be improved without markedly changing its aesthetic appeal?

This depends upon the product but there may have to be a compromise. Floors treated with Floor Coatings or Acid etched will lose some of the ‘shine’ but will make the floor safer. But there are some water-based slip resistance products, with minimal impact to a floor’s appearance. Generally, the shine is one of the factors increasing slip potential.

6.6 - My firm specified and laid a floor surface that was 36 PTV+ compliant but it very slippery – why is this?

The reasons can vary. Soft material floor surfaces like vinyl’s will ‘polish’ in use making floors smoother and more slippery. High footfall in concentrated areas like stairwells, door entrances etc. will also reduce the ability to resist slips. Incorrect cleaning may also be at fault; for example: -

- A floor, which has an incorrect (stronger) dilution of floor detergent will leave the floor more slippery.

- A floor oversprayed with funtiture polish (especially silicon based) will make a floor slippery

- A floor, such as a toilet cleaned with bleach, can leave a residue that will leave floors slippery AVOID USING BLEACH IN WET AREAS LIKE POOLS, JACUZZIS, TOILETS ETC

6.7 - My floor is slippery when wet, can I check to see if it is suitable for use?

Easily. Contact FloorSlip and we can do an On-Site Floor pendulum Test for you. Alternatively, if you can send a sample of the offending floor, then we can Floor Sample Test in in our workshops as well.

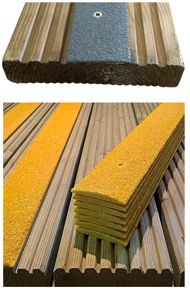

6.8 - Can I make decking less slippery when it is wet?

YES. Firstly, makes sure ALL ‘green’ mildew and algal growth is thoroughly cleaned away. And a better solution is to add anti-slip strips, which are easy to fit and relatively affordable. Try the Timber Cladding Association for further advice (https://www.tdca.org.uk/publications)

6.9 - Does a floor become more slippery as it wears out?

Not always. Vinyl’s can become more slippery. Whereas varnished wooden floors like parquet can become better at resistance slips when the rougher wood is exposed. Hard ceramics wear slowly. Concrete behaves erratically because it depends on the depth and type of the substrate; if sharp angular stone are exposed, the surface becomes rougher so better able to resist slips; If smooth pebbles are exposed, the floor becomes less effective to prevent Slip Injury Claims.

6.10 - I’ve had a floor slip on a carpet. Why?

Carpets generally have a high slip resistance. HOWEVER, furniture spray, particularly that containing silicon, when ‘over sprayed’ from polishing hard furniture, will cause a slippery surface when it lands on the carpet. Many firms now do not allow furniture sprays preferring dusting or damp cleaning with a clean wet cloth of furniture where the furniture will not get damaged.

Section 7 - FOOTWEAR

(OPEN POP UP WINDOW For Acronyms & Glossary)

7.1 - What standards are available for slip resistant footwear?

European standards EN ISO 20344 and BS EN ISO 13287:2007. Using these standards, the UK HSE / HSL (Health and Safety Executive / Laboratories) in conjunction with manufacturers have arrived at non-slip shoe GRIP RATINGS shown as a series of ‘STARS’ from 5, the Highest level of anti-slip; to 1, the Lowest level of anti-slip. See our page on Non-Slip-Shoes

7.2 - Can the slip resistance of footwear be tested?

SATRA (Shoe and Allied Trades Research Association) and the UK HSL (Health & Safety Laboratories) conduct footwear slip resistance testing using a mix of bespoke test apparatus and ramp-testing, typically using EN safety footwear standard EN ISO 20344 and BS EN ISO 13287:2007. Using these standards, the UK HSE / HSL (Health and Safety Executive / Laboratories) in conjunction with manufacturers have arrived at non-slip shoe and boot GRIP RATINGS shown as a series of ‘STARS’ starting from the Lowest level of anti-slip at 1★ (Correct on Web page) to the Highest level of anti-slip at 5★.

Section 8 - LAWS ON FLOORS

(OPEN POP UP WINDOW For Acronyms & Glossary)

8.1 - In 2022, EN-16165 was introduced for floor testing. Does this supersede other tests?

In Dec 2021, European Standard EN-16165 was first issued. The ‘good intent’ was that it would supersede other standards for Ramp Testing and Floor Pendulum Testing (see Floor Testing Standards). Document EN-16165 is a large piece of work and the reality is that the ‘authored work’ doesn’t quite match up with the reality of the floor testing; there are anomalies and shortfalls that have yet to be addressed, which means a mix of the old and new has to be adopted until the EN standard is readdressed (which happens every 4 years!). The UKSRG (in conjunction with the UK HSE/HSL and other leading bodies) will be issuing a new set of Floor Pedestrian Slip Testing Guidelines in 2023 at Issue 6 tied to EN-16165 Annex C (Pendulum Testing) addressing the anomalies. It is expected that the guidelines will then be seen and accepted as the preferred document for testing.

8.2 - What does the UK Law require in terms of slip resistance?

There are various regulations that apply to different premises (see Laws on Floors) and different activities, but essentially, they all require that the floor is not slippery in normal use.

8.3 - What or who is the prime governance in respect to floor safety pendulum testing legislation.

The UK HSE / HSL controlled by the UK government. The UKSRG Guidelines and BS/EN Standards are simply tools to help enforce the government legislation.

Section 9 - BUYING & SPECIFYING FLOORS

(OPEN POP UP WINDOW For Acronyms & Glossary)

9.1 - Which method should I use to specify slip resistance?

To ensure minimal risk from Slip Injury Claims, always specify a Pendulum Test (Currently EN-16165) and mandate floor surfaces like tiles or vinyl’s that can be tested prior to laying are Pendulum Sample Tested in advance.

9.2 - Can I use R Ratings (R9, R10, R11, R12 or R13) or ABC Rating to select floors?

NO. R-Ratings are for specific set of circumstances and not for generic specification. E.g., a company that has workers wearing company issued safety boots walking on a specific floor surface that is likely to get contaminated with oil, might decide to get a ramp test done to evaluate the ability of boot, contaminant and floor surface to work together to provide a safe floor surface. The same principal applies for ABC Ratings, which is for bare foot applications only, where a specific floor type / contaminant is tested and not for generic specification.

9.3 - As a floor specifier / architect, am I open for prosecution if I specify floors, which cause slips when wet?

That will depend. If as a specifier, you follow a regimen and CAN FORMALLY PROVE (emails, letters etc.) that you gave ‘due diligence’ to determine what a safe floor would be through checking specifications, getting Floor Samples Tested and insisting upon On-Site Pendulum Tests at first fit, then you should be in a strong position of defence against a claim of negligence for Slip Injury. If on the other hand, you simply specified a floor surface because that’s what the customer wanted (generally based on price, availability and aesthetic appearance) without ‘effectively considering’ floor safety, then you will most likely have more difficulty to prove that you took all reasonably practicable steps to ensure the safety of users .Customers know what they want, but they don’t always know what is safe or legal; it is highly likely that your task as specifier / architect etc. is to be cognisant of the facts and point out these facts to the Customers.

9.4 - What vinyl floor coverings retain slip resistant values for a reasonable life?

Use a Vinyl from a reputable source who manufacture to BS EN 13845 (Titled; Resilient floor coverings – Polyvinyl chloride floor coverings with particle based enhanced slip resistance – Specification). Many of these Vinyl’s have up to 10 years guaranteed slip resistance . Suppliers will probably provide a sample that can be independently Floor Sample Tested; they should also provide a specification sheet stating the WET PTV values will remain at > 36PTV

9.5 - When do I definitely need to specify a floor with a minimum of 36 PTV when wet?

A floor surface of 36PTV at horizontal floor slope when tested wet is ALWAYS required if, for example:

- The floor surface will always become wet, like a pavement

- Or is more than likely to become wet (or contaminated) on a regular basis, e.g., near an external door entrance

- Or is a shop front entrance open to the elements

- Or is an external covered pathway where windblown rain occurs

- Or in a multi storied car park where tyres / cars will transmit water

- Or on an escalator where trolleys brought in form a wet enviroenemnt are used on the escalator

9.6 - When are floors with ‘moderate potential for slip’ recommended?

A MODERATE slip potential is a value that is worse (lower) than 36PTV and is unlikely to be ‘recommended’. Wherever possible, always aim for a floor with a LOW slip Potential, which is a value of 36PTV+ when wet tested on a horizontal slope. It may trasnpire that you can apply ALARP when using a floor less than 36 PTV when wet tested - see the Scetions on Floor Safety ALARP and on Floor Safety Risk Assessments

9.7 - Is it possible that a homogenous floor (same surface finish throughout) can have different areas of slip resistance?

YES. Floors wear due to footfall, trolleys, pallet trucks, vehicles and degrade through age, solar degradation and chemicals from cleaning. The wear / degradation will change Pendulum Test Values, sometime dramatically.

9.8 - Do Different standards apply to different flooring materials?

YES, there are lots of standards for flooring materials. You may get some good ideas from our pages on ‘All Floor Surfaces Relevant Standards’

9.9 - What slip resistance level is required in, for example, a school corridor or class room?

The slip resistance required is always dependent upon the use of the individual area and also whether persons (or the likes of wheeled trolleys) transiting through can bring in water or contaminants to affect the floor. If the likelihood is that it will become wet (for example in a school with children bringing in water and snow etc. on shoes and clothing or from spilt drinks or activity playthings) then always aim at a floor with 36PTV when wet tested (adjusted upwards for floor slopes)

9.10 - What is the UK HSE ‘SAT’?

The SAT is the UK HSE Slip Assessment Tool, a free online tool to assist (only) in assessing the slip potential of pedestrian walkway surfaces in conjunction with a Surface Roughness Tester to determine Rz Values (Approx cost £2000+). IT SHOULD BE CLEARLY NOTED THAT THE RZ VALUES ARE A REINFORCEMENT TO PENDULUM TEST DATA AND NOT INSTEAD OF. and in the event of a conflict in readings between the two, the Pendulum test readings always take precedence. The UK HSE website gives the impression that the SAT will be the only tool needed for the layman to assess the floor surfaces. In our opinion, this is a misleading statement as two surfaces that measure the same surface microroughness readings can have markedly different Pendulum Test Values (PTV). It is the PTV value (determined by On-Site Floor Pendulum Testing or Off-Site Floor Sample Testing) that is the value that the UK Courts in Slip Injury Claims generally recognise and the PTV is the only value that gives a true measure of ‘Dynamic’ slip resistance.

SAT Links on the UK HSE Site

https://www.hse.gov.uk/slips/sat/default.htm

https://www.hse.gov.uk/slips/sat/faqgeneral.htm

https://www.hse.gov.uk/slips/sat/index.htm

Section 10 - UK HSE

(OPEN POP UP WINDOW For Acronyms & Glossary)

10.1 - What is the HSE online STEP tool?

The STEP or ‘Slip and Trip E-learning Package’is a low-price online tool to assist in learning: -

- Why slips and trips happen and the risks, environmental and local contaminants, human factors and hazards involved

- How to prevent Slip Injury Accidents through appropriate cleaning, selecting the correct flooring materials and footwear

- How to conduct a risk assessment, understand effective communication, report incidents and legislation

10.2 - The data on the UK Gov HSE website indicates to use UKSRG Guidelines as well as BS-7976-2 but not EN-16165 to date. Which should be used and who is the governing body?

In these days of government cuts, the UK HSE could be viewed as being short of staff and short of funds. As a result, the websites are not always up to date and instead they rely on recognised established bodies such as the UKSRG for advice and guidance; the likes of the UKSRG are in some cases populated with ex-HSE staff. In terms of what floor pedestrian standards and guidelines to use then ideally use: -

- EN-16165 with UKSRG Guidelines Issue 6 (Preferred most recent standard) - – see our page ‘Pedestrian Floor Testing Standards’

- BS-7976-2 with UKSRG Guidelines Issue 5 (Historical but still partly in use

- BS-EN-13036-4 does not have a UKSRG Guidelines allied to it by the BS procedure is very similar to BS-7976-2 and EN-16165 – see Road and Airfield Test Procedures

10.3 - EN 16165 is due for release in 2021/ 2022. Is it known if the HSE will adopt EN 16165 as the only standard and update guidance on line to inform about this?

It is believed and it is our understanding from HSE sources who interface with the UKSRG that the UK HSE will adopt EN-16165

Section 11 - UKSRG

Note FloorSlip are members of UKSRG and the questions raised and answers given are top-level and generic in nature only and therefore it is felt can be included here.

If you require UKSRG specific answers then please Contact the UKSRG or the UKSRG Members.

(OPEN POP UP WINDOW For Acronyms & Glossary)

11.1 - Will EN-16165 remove the need for UKSRG Guidelines?

NO. The Guidelines (to be released at issue 6 in 2023 to align with EN-16165) are absolutely necessary to bring enhance / augment EN-16165 and to correct for any anomalies / conflicts that EN-16165 might introduce by integrating a European Standard into the UK. Furthermore, EN-16165 will not be updated until late 2025 / 2026; 4 years after publish date on 31 Dec 2021 so in th einterim, the UKSRG guidelines are necessary (and affordable)

11.2 - Can UKSRG guidelines be officially included into UK Court reports?

YES. Extracts may be used in the same manner that data from the HSE and from British or European standards or Building Regulations applicable to floor safety may be used as long as its source is declared and not falsely manipulated.

11.3 - Are UKSRG Guidelines applicable to vehicular traffic in car parks?

The UKSRG focuses on pedestrian safety for pedestrians in the car park but this is not extended to the slip resistance required by vehicles.

BS-EN-13036-4 is applicable to Roads (and Airfield Runways) and the UKSRG do not publish a guide associated with BS-EN-13036-4. But note, BS-7976-2, EN-16165 and BS-EN-13036-4 all cover the same testing and use the same Pendulum Test Equipment so the UKSRG guidelines could very well be applied in a large percentage of the subject matter.

11.4 - Will a new UKSRG Guidelines be issued to align with EN-16165?

YES. Issue 6 of the UKSRG is due for release in 2023 and will include the changes brought about by EN-16165 (2022). (Note - Issue 5 was written around BS-7976).

11.5 - How much do the UKSRG Guidelines cost?

- Issue 5 (Against BS-7976-2) - £60

- Issue 6 (Against EN-16165) See the UKSRG Website at https://www.ukslipresistance.org.uk/publication/uk-guidelines/

11.6 - Do the UKSRG publish other data as well as UKSRG Guidelines?

YES. See the UKSRG website at: -

UKSRG Publications

https://www.ukslipresistance.org.uk/guidance-and-faqs/uksrg-publications/

Guest Publications

https://www.ukslipresistance.org.uk/guidance-and-faqs/guest-publications/

End of FAQ's - If you have any questions at all or wish to add to the FAQ's then please send an email to mark@floorslip.co.uk or contact one of the highly skilled FloorSlip Agents