Sales of NEW UK made Floor Pendulum Testing Equipment

FloorSlip provide Pendulum Floor Testing Equipment built to British Standards to customers in the UK, Europe and Worldwide.

We have a long standing arrangment with one of the UK's leading suppliers of Pendulum Floor Testing Equipment; often selling at prices cheaper than the suppliers!

Training - We can also train you / your company in the use of your equipment on-site (UK Only) for equipment purchased from us or your own equipment. Our Pendulum Floor Testing Training Courses can cater up to 6 persons at once and are conducted at your establishment, removing the costs for you associated with sending 6 people to a training centre.

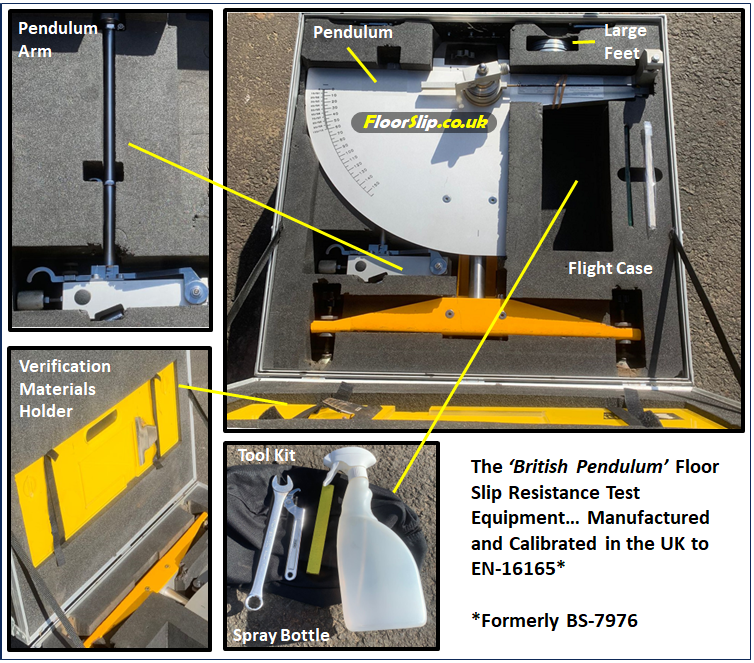

What's included in the sale of the floor testing equipment?

- Very sturdy 'Flight Case' (measuring approx 900 x 900 x 350 mm)

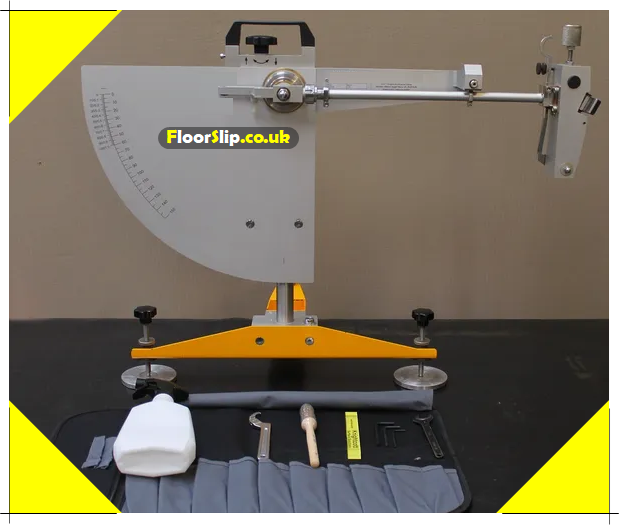

- The Pendulum Test Equipment

- 2 Rubber Sliders (#55 and #96)

- Toolkit

- Water Bottle

- Footprint Gauge

- Thermometer

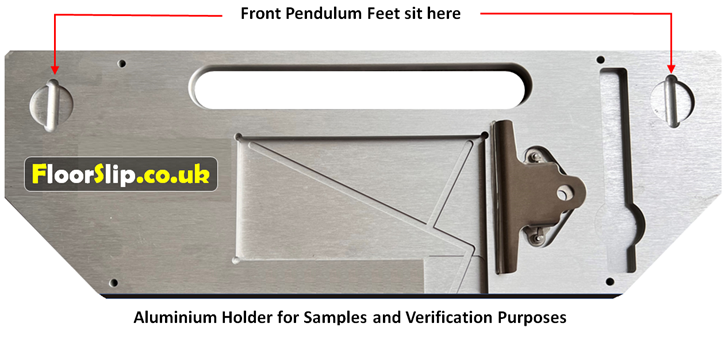

- Pavigres Tile (For Pendulum Verification)

- Green Lapping Paper (For Pendulum Verification)

Price? - See our Prices Page

Optional Extras (At additional Cost, quoted at time of order)

- Float Glass (Required for Pendulum Verification)

- Extra Rubber Sliders (#55, #96, #57 not yet available)

- Large Format Feet (3 off) for soft floor surfaces like vinyls and wood

- Verification Materials holder

Equipment Availability

The equipment can 'sometimes' be supplied within a few days, but generally, around 6 weeks. Every piece of Pendulum Test Equipment is handbuilt and manufactured from scratch. It is made from UK engineered, manufactured and supplied piece parts and good quality takes time.

Are these imported Pendulum Test Equipments?

DEFINITELY NOT! And we advise anybody considering getting one of the 'cheaper' UK imports from the 'east' not to buy these.

They are cheaper for a reason, or in this case, many reasons as follows....

Imported Items...

- ...are NOT manufactured to British Standards

- ... do NOT always give accurate readings

- ... often do NOT manage to pass Pendulum Verification (critical in any test)

- ...do NOT have an availability of spares (where as UK supplied / manufactured are easy to source)

- ... can NOT generally be repaired in the UK,

- ... can NOT generally be Calibrated in the UK, which is CRITICAL and required annually to ensure accuracy and correctness and to meet UK HSE expectations for floor safety.